In the field of scientific research, finding a material that combines both metallic and ceramic properties has long been a dream for scientists. The Ti3AlC2/MXene material we are introducing today is precisely such a remarkable existence. It not only exhibits excellent electrical conductivity and thermal stability but also features a unique layered structure, allowing it to stand out in numerous applications.

This material is widely used in cutting-edge fields such as energy storage, catalysis, and sensors. Its easily etchable and exfoliable nature enables researchers to effortlessly obtain single-layer or few-layer MXene nanosheets, greatly facilitating experiments.

What is MAX phase?

The MAX phase is a type of ternary layered ceramic material, where M represents transition metal elements, A refers to elements from the III and IV main groups, and X stands for carbon or nitrogen. The crystal unit of this material has a hexagonal structure with a space group of P63/mmc, where M atom layers and A atom layers alternate, forming a layered structure similar to hexagonal close packing, while the X atoms fill the octahedral voids.

M represents transition metal elements, A represents main group elements, and X represents carbon or nitrogen atoms, with n = 1, 2, 3, hence it is referred to as the MAX phase. When n = 1, it is the 211 phase, such as Ti₂AlC and Ti₂SiC; when n = 2, it is the 312 phase, such as Ti₃SiC₂ and Ti₃AlC₂; when n = 3, it is referred to as the 413 phase, such as Ti₄AlN₃. MAX phase synthesis is mainly achieved by ball milling the raw powder mixture followed by high-temperature sintering.

What's the propertie of Ti3AlC2?

- Thermal Stability: Ti3AlC2 exhibits excellent thermal stability, maintaining structural integrity and performance at high temperatures.

- Mechanical Properties: It has strong mechanical properties, such as high strength and hardness, making it suitable for the preparation of high-performance structural materials.

- Electrical Conductivity: Due to its layered structure, Ti3AlC2 has good electrical conductivity in the vertical direction, making it useful for the preparation of conductive ceramic materials.

- Corrosion Resistance: It has certain resistance to chemical corrosion, making it suitable for applications in harsh environments.

Structure of Titanium Aluminum Carbide

Titanium aluminum carbide (Ti3AlC2) belongs to the hexagonal crystal system and possesses both metallic and ceramic properties: it has the electrical and thermal conductivity typical of metals, as well as the high elastic modulus and excellent high-temperature mechanical properties similar to ceramics. Additionally, it has good thermal shock resistance, damage tolerance, and outstanding chemical corrosion resistance.

Ti3AlC2 Powder Parameters:

Purity: > 99%

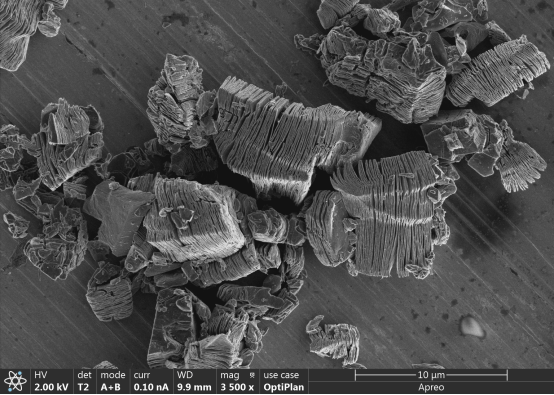

Particle size: < 10 microns (can be provided according to customer requirements)

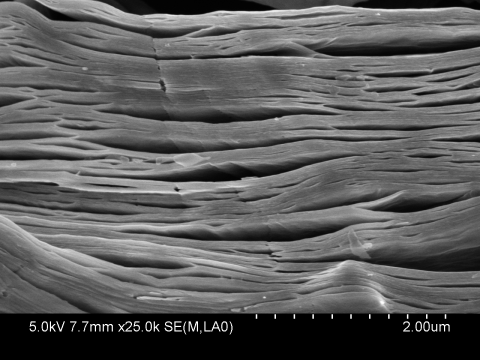

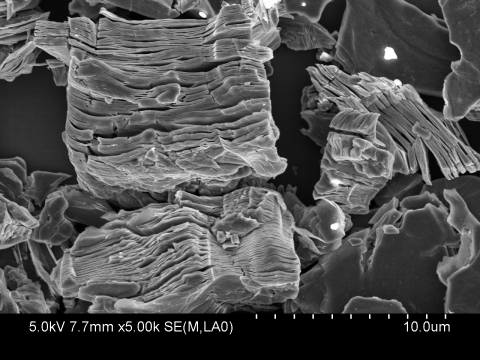

Grain morphology: Lamellar.

Molecular Formula

Ti3AlC2

a (nm):

0.3075

c (nm):

1.8578

Density (g/cm³)

4.5

Vickers Hardness (GPa)

2.5 ~ 3.5

Compressive Strength (MPa)

764

Bending Strength (MPa)

320 ~ 375

Fracture Toughness (MPa·m¹/²)

6.9 ~ 9.5

Poisson’s Ratio

0.2

Electrical Resistivity (μΩ·m)

0.23 ~ 0.387

Young’s Modulus (GPa)

297

Shear Modulus (GPa)

124

What’s the application of Ti3AlC2 powder?

Titanium carbide aluminum (Ti3AlC2 and Ti2AlC) has high-temperature self-healing capabilities due to the microstructure at the interface between the generated Al₂O₃ and the material. At high temperatures, cracks or scratches on the material’s surface are filled by this oxide, allowing the material to restore its original properties, especially mechanical properties. This feature is crucial for maintaining the material’s mechanical performance and improving its stability and reliability, making it more promising for use in high-temperature environments.

The rapid diffusion of Al and selective oxidation at high temperatures enable the material’s self-welding and bonding between layers. The fracture toughness of the self-welded layered material is significantly improved compared to single-phase materials.

Such materials can be widely used as high-temperature structural materials, electrode brush materials, chemical corrosion-resistant materials, and high-temperature heating elements. These products are mainly used for high-temperature coatings, MXene precursors, conductive self-lubricating ceramics, lithium-ion batteries, supercapacitors, and electrochemical catalysis.

Storage Conditions for Ti3AlC2 powder:

Store at room temperature in a dry, light-protected, and sealed environment with AR protection.

For researchers, selecting the right material is crucial. High-quality raw materials not only improve the success rate of experiments but also save a lot of time and effort.

VIMATERIAL offers various MAX phase and MXene nanosheets, such as Ti₃AlC₂, Ti₂AlC, Nb₂AlC, and Ti₃C₂Tx, Ti₂CTx, Nb₂CTx, V₄C₃Tx, Ti₃CN, and more. Taking Ti₃AlC₂ as an example, we provide multilayer MXene nanosheets in accordion-like (HF-etched) and clay-like (LiF + HCl-etched) forms, as well as single-layer (~1nm), thin-layer (1-5nm), and few-layer (1-10nm) MXene nanosheets obtained through ultrasonic exfoliation, along with dispersion liquids.

- Adjustable size and thickness: We can provide MXene nanosheets with various sheet sizes and thicknesses.

- Good hydrophilicity: With abundant surface functional groups, it shows good dispersion in aqueous solvents.

- Good conductivity: The alternating layers of carbon and transition metals impart excellent electrical conductivity and pseudocapacitance properties to MXene.

- Two-dimensional layered structure: Large specific surface area, numerous surface reactive sites, and excellent catalytic performance.