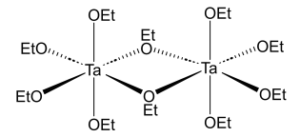

Tantalum(V) ethoxide is a kind of metalalkoxides, with the formula Ta(OEt)5,usually exists in the form of dimerTa2(OEt)10. It hydrolyzes readily, and isoften used to prepare films of Ta2O5.

Vimaterial is an expert in thin film materials. If you have any needs, please feel free to contact us.

Name: Tantalum(V) ethoxide

Assay: ≥99.98%

Ta Content: 44-46%

Synonym(s): Tantalum ethoxide, Tantalum pentaethoxide, Tantalum ethylate

| CAS | 6074-84-6 | 18°C to 19°C | |

| Formula | Ta(OCH2CH3)5 | Boiling Point | 145°C (0.1mmHg) |

| Appearance | Colorless liquid or white soild | Flash Point | 30°C (86°F) |

| Molecular Weight (g/mol) | 406.25 | Refractive Index | 1.488 |

| Density | 1.566 g/ml (25℃) | SMILES | CCO[Ta](OCC)(OCC)(OCC)OCC |

| UN Number | UN2920 | InChI Key | HSXKFDGTKKAEHL-UHFFFAOYSA-N |

| Solubility | Soluble in organic solvents. | Sensitivity | Air and moisture sensitive |

The hydrolysis reaction of tantalum produces tantalum pentoxide thin films andgels, with the overall reaction equation as follows:

Ta2(OEt)10 + 5 H2O → Ta2O5 + 10 EtOH

Tantalum ethoxide is an ideal precursor of tantalum oxide and is widely used in high-tech fields such as IC insulation materials, electrolytic anode surface coatings, memory, catalysts, and the preparation of ultra-high purity ultra-fine tantalum pentoxide powder.

Electrochemical Synthesis

Compared to the traditional hydrolysis method from TaCl5, electrochemical synthesis offers advantages such as environmental friendliness (no use of ammonia or benzene), minimal waste generation, and low chloride ion content in the final product.

anode:

Ta→Ta5+ + 5 e–

cathode:

2 EtOH + 2 e– → 2EtO– + H2↑

overall:

2 Ta + 10 EtOH → Ta2(OEt)10 + 5H2↑

Sensitive to moisture and air. Please keep the container tightly closed and store in a dry and ventilated place. Incompatible with strong oxidants.

Warning

Serious eye damage/eye irritation Category 2

Flammable liquid Category 3

Skin corrosion/irritation Category 2

Specific target organ toxicity Category 3

H226-Flammable liquid and vapour.

H315-Causes skin irritation.

H319-Causes serious eye irritation.

H335-May cause respiratory irritation.

P210-Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking.

P261-Avoid breathing dust/fume/gas/mist/vapours/spray.

P280-Wear protective gloves/protective clothing/eye protection/face protection.

P302+P352-IF ON SKIN: Wash with plenty of water/soap.

P305+P351+P338-IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) employs a stringent quality assurance system to ensure the reliability of our product quality. Strict quality control is implemented throughout the entire production chain, and for defective products, we strictly enforce the principle of rework and redo. Each batch is released only after passing detailed specification tests.

Every batch of our materials is independently tested, and, if necessary, we send samples to certified companies for testing. We provide these documents and analysis certificates with the shipment to certify that our products meet the required standards.

Contact our team of experts today and let us help you with your business!