INORGANIC MATERIALS

SPECIALIST

Who is VIMATERIAL?

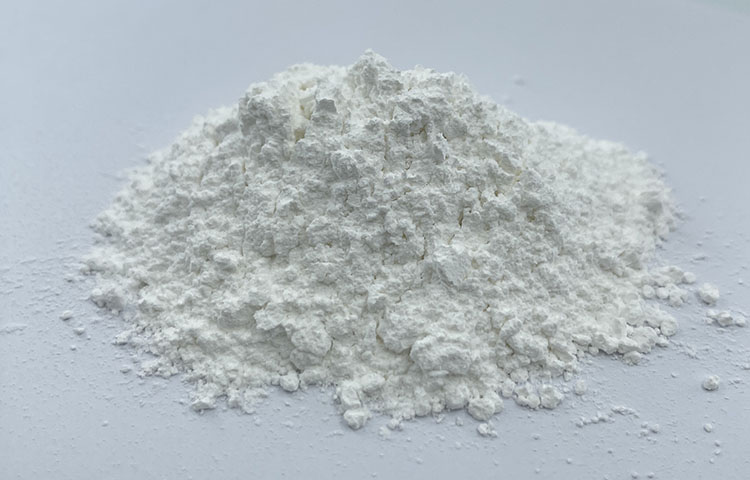

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) primarily provides high-purity thin film coating materials and inorganic chemical powder materials, aimed at meeting the research and development needs across various industries. Our thin film coating products include pure metal targets, alloy targets, ceramic targets, and evaporation materials. Our inorganic chemical powder products include high-purity metal and alloy powders, rare earth materials, chalcogenides, halides, nitrides, carbides, borides, and silicides, among other advanced materials. These products are widely used in the semiconductor, aerospace, electronics, photovoltaic, optical, and new energy sectors.

Semiconductor Materials

We offer super high-purity thin film coating materials that are essential for cutting-edge semiconductor research and manufacturing.

New Energy

We specialize in researching various advanced materials and offer tailored solutions to meet your unique needs, supporting innovative research and development in the new energy industry.

Optics Coatings

We stay up-to-date with the latest technology trends and offer high-purity optical crystal materials for cutting-edge optical research and applications.

Solar

Our products are essential for the solar industry, delivering high-purity advanced materials that enhance the efficiency and performance of photovoltaic technologies.

QUALITY ASSURANCE

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) employs a stringent quality assurance system to ensure the reliability of our product quality. Strict quality control is implemented throughout the entire production chain, and for defective products, we strictly enforce the principle of rework and redo. Each batch is released only after passing detailed specification tests.

Every batch of our materials is independently tested, and, if necessary, we send samples to certified companies for testing. We provide these documents and analysis certificates with the shipment to certify that our products meet the required standards.

Knowledge Base

Become a VIMATERIAL partner now!

We’re happy to answer any questions you may have and help you determine which materials best fit your needs.

Why Choose Us?

- Client-oriented

- Small/Large quantity

- Comprehensive

Contact Us Now !

Our Technology Partners

We have long-standing partnerships with numerous certification companies to ensure our products meet customer requirements and standards.