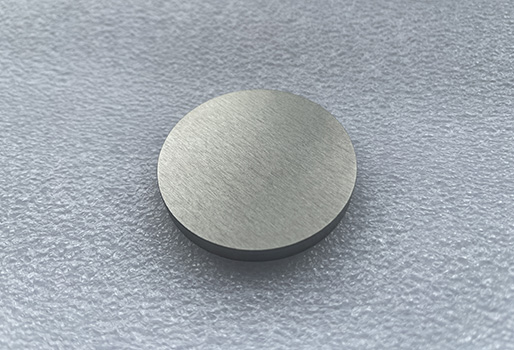

Zirconium sputtering targets are disc-shaped or plate-shaped materials made from zirconium, primarily used in the sputtering deposition process in the electronics industry. During high-temperature sputtering, these targets are deposited onto substrates to form the desired thin film materials.

In advanced thin film preparation technologies, the choice of target material plays a decisive role in the performance of the final film. Zirconium targets are increasingly becoming an essential component in the semiconductor, optoelectronic, optical coating, and functional coating industries.

I. Basic Characteristics of Zirconium Target

Zirconium (Zr) is a grayish-white metal with a density of about 6.51 g/cm³ and a melting point as high as 1855°C. It possesses the following outstanding characteristics:

High melting point and strength: Suitable for thin film deposition under high-temperature conditions;

Excellent corrosion resistance: Strong resistance to acids, alkalis, and saline solutions;

Good electrical and thermal conductivity: Ensures stable energy transfer during sputtering;

High purity for low-defect films: High-purity zirconium targets effectively reduce impurities, improving film density and uniformity.

II. Types of Zirconium Zr Sputtering Targets

According to different applications and equipment requirements, zirconium targets are generally classified into the following types:

Circular Target: Commonly used in magnetron sputtering systems;

Planar Target: Suitable for large-area coating production lines;

Rotary Target: Improves utilization rate and deposition efficiency, commonly used in industrial-scale production.

In addition, products of various purities (99.5%–99.99%) and customized dimensions can be provided according to specific process requirements.

III. Application Fields of Zirconium Sputtering Target

Due to its excellent physical and chemical properties, zirconium targets are widely used in various high-tech industries:

Electronics and Information Industry

Zirconium targets are used to prepare zirconium-based films with excellent dielectric properties. These films effectively control electron transport and storage, reduce signal interference, and improve display clarity and response speed.

2. Semiconductor Chip Manufacturing

Zirconium targets are used in metallization processes during semiconductor fabrication. The deposited zirconium thin films can serve as barrier or adhesion layers.

Optical Industry

1. Optical Coating

Zirconium oxide films formed from zirconium targets feature a high refractive index and low absorption coefficient. When deposited on optical components, these films enhance light transmittance, reduce reflection loss, and improve imaging quality in optical systems.

2. Optical Fiber Manufacturing

Zirconium targets are used to produce coatings on optical fiber preforms. The resulting coating protects the fiber core from environmental corrosion while adjusting the refractive index profile, enabling efficient optical signal transmission.

New Energy Industry

1. Solar Cells

For crystalline silicon solar cells, zirconium thin films can serve as surface passivation layers, reducing electron recombination on the silicon surface and improving photoelectric conversion efficiency.

In thin-film solar cells, such as CIGS (Cu(In,Ga)Se₂) cells, zirconium can act as a buffer layer material to optimize the internal energy band structure, facilitate charge carrier separation and collection, and enhance overall cell performance.

2. Lithium-Ion Batteries

To improve the safety, cycle life, and energy density of lithium-ion batteries, material innovation is crucial. Zirconium oxides or composite oxides can be prepared using zirconium targets and applied to electrode materials or separator coatings.

Decorative and Protective Applications

1. Jewelry Surface Treatment

Zirconium targets are used in coating processes to form a zirconium film with diamond-like luster on jewelry surfaces. These films have extremely high hardness, excellent scratch resistance, and diverse colors. By adjusting coating parameters, various gemstone-like hues can be simulated, adding luxurious aesthetics to jewelry.

2. Aerospace Material Protection

In the aerospace field, zirconium targets are primarily used to produce high-performance alloys with exceptional mechanical strength and corrosion resistance. The addition of zirconium significantly enhances the overall performance of alloys, making them more reliable and durable for aerospace applications.

IV. Preparation and Quality Control of Zirconium Targets

Manufacturing Process

Smelting: High-purity zirconium oxide is reduced to metallic zirconium in an electric arc furnace or induction furnace under controlled temperature and atmosphere to prevent contamination.

Casting: The molten zirconium is cast into ingots in a high-purity inert gas environment to ensure material purity and structural integrity.

Rolling: The cast zirconium ingots are processed through hot and cold rolling to achieve the required thickness and shape. Repeated heating and cooling improve material density and uniformity.

Surface Treatment and Quality Control

Surface Treatment: Before use, zirconium targets undergo surface treatments such as chemical or mechanical polishing to remove oxides and surface impurities.

Quality Control: Advanced analytical instruments such as X-ray Fluorescence (XRF) and Inductively Coupled Plasma Mass Spectrometry (ICP-MS) are used to rigorously test purity and uniformity, ensuring compliance with high-tech application standards.

V. Advantages of VIMATERIAL Zirconium Sputtering Targets

VIMATERIAL offers high-purity zirconium sputtering targets with the following features:

High purity (≥99.95%) and low oxygen content;

Uniform microstructure, high density, and no cracks;

High dimensional accuracy and excellent surface finish

Available in circular, planar, and rotary target forms;

Custom fabrication available upon request;

Excellent target-to-backing plate bonding performance.

VI. Conclusion

With the continuous advancement of thin film technologies, the demand for higher purity, density, and stability in target materials continues to rise.

Thanks to its outstanding physical properties and wide applicability, zirconium target has become an important choice for high-end coating materials.

VIMATERIAL is committed to providing customers with high-purity, high-performance zirconium target solutions, supporting the achievement of superior quality and efficiency in thin film deposition processes.