Zirconium, a silvery-white transition metal, may not shine like gold or silver, yet with its strong resistance to corrosion and high temperatures, along with its low neutron absorption capacity, it has become the “invisible guardian” of nuclear energy and advanced manufacturing.

As the world undergoes energy transformation and upgrades in high-end manufacturing, zirconium is evolving from a supporting role in traditional industries to a core material in emerging sectors, continuously unlocking its value potential.

Performance Advantages

The core competitiveness of Zr lies in its unique atomic structure—the dense oxide film (ZrO₂) formed by its outer electron configuration enables it to remain stable in extreme environments of high temperature, high pressure, and strong corrosion.

Experimental data show that the corrosion rate of zirconium in seawater at 300 °C is only 1/100 that of stainless steel, and it can still maintain mechanical properties in steam at 500 °C. With a melting point as high as 1852 °C and slow strength degradation at elevated temperatures, zirconium is regarded as an ideal material for nuclear fuel cladding.

In addition, its low thermal neutron absorption cross-section effectively reduces neutron loss and enhances nuclear reaction efficiency, further reinforcing its irreplaceable role in the nuclear industry.

Is Zirconium a Metal Nonmetal or Metalloid?

Zirconium belongs to Group IV-B of the periodic table, with an atomic number of 40, a density of 6.49 g/cm³, a melting point of 1852 °C, and a boiling point of 4377 °C. It is a silvery-white transition metal and is often referred to as a “rare metal” due to its complex extraction process. In fact, zirconium accounts for about 0.025% of the Earth’s crust, ranking 19th in abundance—almost equal to chromium and even more plentiful than common metals such as copper, lead, nickel, and zinc, though it is widely dispersed.

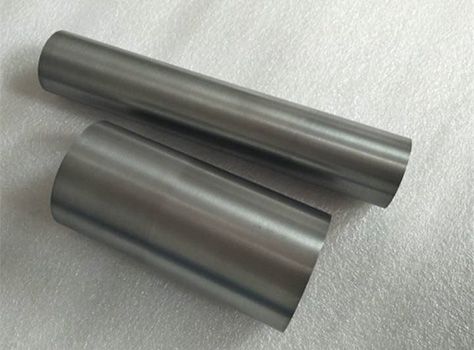

Zr is highly corrosion-resistant but dissolves in hydrofluoric acid and aqua regia; at high temperatures, it can react with many elements to form solid solution compounds. Its corrosion resistance surpasses that of titanium and is comparable to that of tantalum and niobium. Owing to its good plasticity, zirconium is often processed into plates, wires, and other forms.

What is black zirconium metal?

Black Zr metal is caused by the formation of a hard black zirconia layer on the zirconium surface due to oxidation, or by the residue of black substances such as lubricants or anti-corrosion agents during processing.

- Surface Oxidation:The surface of zr metal is easily affected by oxygen in the air. When exposed for long periods, it gradually oxidizes to form zirconia, turning the surface black. In this case, the black layer is usually thin and can often be removed by friction or wiping.

- Attachment of Black Substances:During processes such as injection molding, lubricants or anti-corrosion agents may be used, which can remain on the zirconium surface and form black deposits. Such substances usually cannot be easily removed by wiping or friction.

How to remove the blackened Zirconium Surfaces?

Surface Oxidation: Oxidation of zirconium metal is generally irreversible, but its progression can be controlled. For example, using inert gases such as argon during manufacturing can slow down oxidation, while applying a protective coating on the surface can also help reduce oxidation.

Attachment of Black Substances: If the blackening is caused by processing residues, alternative lubricants, anti-corrosion agents, or modified injection molding methods may reduce deposits. For already contaminated surfaces, chemical reagents or high-temperature, high-pressure cleaning can be used for removal.

What are the uses of zirconium metal?

The “Stabilizer” of Nuclear Energy:

Zirconium metal has a low thermal neutron absorption cross-section, excellent corrosion resistance, and outstanding high-temperature stability, making it an ideal material in the nuclear industry. More than 90% of nuclear power plants worldwide use zirconium alloys (such as Zr-2 and Zr-4) as cladding materials for fuel rods.

“Heat-Resistant Pioneer” in Aerospace:

Aerospace applications demand materials with high strength, low density, and excellent heat resistance. Zr meets these requirements and is used in high-temperature components such as combustion chambers and turbine blades of jet engines, as well as key parts of rocket engines.

“Safe Guardian” in Biomedical Applications:

Medical zirconium alloys (such as Zr-Nb-Ta systems) have better biocompatibility than titanium alloys and are free from magnetic interference during MRI scans. They are widely applied in artificial joints, dental implants, and other medical devices, improving treatment outcomes and quality of life for patients.

“Etching Tool” in Semiconductors:

High-purity zirconium (99.999%) is the core raw material for producing zirconium tetrachloride (ZrCl₄), an etching gas used in deep-etching processes for 12-inch wafer manufacturing. With advanced semiconductor nodes (below 3 nm) requiring nanometer-scale etching precision, the demand for high-purity zirconium is growing at an annual rate of 12%, making it a new growth driver in semiconductor materials.

From the Deep Sea to Outer Space, From Microchips to Energy Systems, Zr metal, as an “invisible guardian,” supports humanity’s pursuit of an efficient, safe, and sustainable future. With continuous technological innovation and industrial upgrading, this “jewel among transition metals” is destined to shine even more brilliantly.