When you think of things that shine in the dark—glow-in-the-dark star stickers on ceilings, novelty toys, or even the hands of old wristwatches—you’re most likely thinking of a remarkable compound called zinc sulfide. But this material is far more than just a quirky light source. It is a true workhorse of the inorganic world, combining fascinating physical and chemical properties that make it indispensable across industries ranging from optics to electronics. So, what makes zinc sulfide so unique? Let’s dive into the luminous world of this multifunctional material.

What is Zinc Sulfide? The Fundamentals

At its most basic, zinc sulfide (chemical formula ZnS) is an inorganic compound and a classic II–VI semiconductor material. In nature, it mainly occurs in two mineral forms:

Sphalerite (zinc blende): The most common and stable form of ZnS. It crystallizes in a cubic structure and is the primary ore of zinc. If you’ve ever seen a dark, resinous mineral with a diamond-like luster, chances are it was sphalerite.

Wurtzite: A rarer hexagonal form of ZnS, stable at higher temperatures. Its structure, named after the mineral wurtzite, is of great importance in materials science.

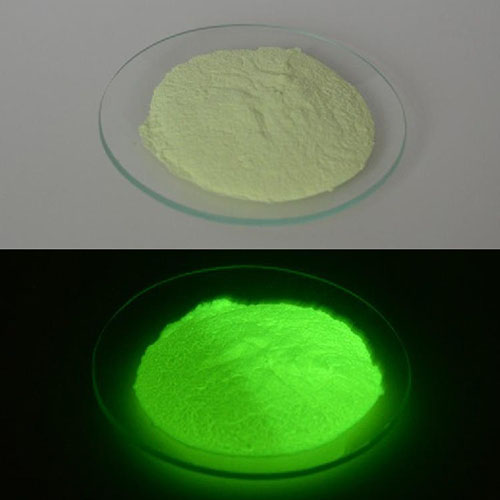

While ZnS does occur naturally, most of the zinc sulfide used in industry is synthetically produced. Controlled synthesis allows for extremely high purity and precise particle sizes—critical for advanced applications. In its pure form, zinc sulfide appears as a white to pale yellow powder, but what truly sets it apart is how it behaves when exposed to energy.

A Versatile Material: The Physical Properties

The applications of zinc sulfide are directly tied to its unique set of physical properties. Understanding these helps explain why it’s used in such diverse fields.

Bandgap: This is a crucial semiconductor property. ZnS has a wide band gap of approximately 3.6-3.8 eV for the sphalerite form. This makes it an excellent insulator in its pure form, but its electronic properties can be finely tuned through doping for use in optoelectronics.

Refractive Index: ZnS is notable for its high refractive index (~2.35). This allows it to bend light significantly, making it an ideal material for lenses and optical windows. Its chemical stability further enhances its performance in such applications.

Solubility: Zinc sulfide is nearly insoluble in water, a property that contributes to its durability as a pigment and its reliability in humid environments. However, in strong acidic conditions, ZnS will decompose.

Melting Point: Under high pressure, ZnS has a melting point of around 1,850 °C (3,362 °F). This thermal stability makes it suitable for demanding environments.

Hardness: On the Mohs scale, sphalerite has a hardness of about 3.5–4, which places it among relatively soft minerals. This factor must be considered during the machining and polishing of optical components.

Density: Sphalerite ZnS has a density of approximately 4.09 g/cm³.

Luminescence: Perhaps its most famous property, ZnS exhibits fluorescence and phosphorescence when excited, enabling its widespread use in lighting, displays, and glow-in-the-dark products.

The Magic of Luminescence: Does Zinc Sulfide Glow in the Dark?

The short answer is yes—but with one very important condition.

Pure zinc sulfide on its own does not glow in the dark. Its fascinating property is known as photoluminescence. To emit light, it must first be “charged” with an energy source, most commonly ultraviolet light. When UV photons strike the ZnS crystal, they excite electrons within the material to higher energy states. As these electrons eventually return to their stable ground state, they release the stored energy in the form of visible light—this is the glow we observe. That’s why luminescent zinc sulfide-based products shine brightly under a black light, but fade quickly once the external energy source is removed.

To create the classic long-lasting “glow-in-the-dark” effect, zinc sulfide must be doped with activators, most commonly copper (which produces a green glow) or silver (which produces a blue glow). Doping introduces defects into the crystal lattice, which serve as trapping sites for excited electrons. These sites slowly release energy over time, producing the familiar persistent phosphorescence of glow-in-the-dark materials. This doped material is typically known as copper doped zinc sulfide (ZnS:Cu).

It is worth noting that while ZnS phosphors were the industry standard for decades, newer materials such as strontium aluminate doped with europium and dysprosium now dominate due to their brighter and longer-lasting glow. Even so, zinc sulfide remains widely used thanks to its cost-effectiveness and classic performance.

Specifications: Tailored Forms

Beyond its fundamental chemistry and luminescence principles, zinc sulfide is produced in various forms and purity levels to meet application-specific needs. Understanding these specifications is key to choosing the right ZnS for the right application.

Commercial ZnS products are generally divided into three categories: sintered products, crystals, and powders. Each form has its own preparation methods, purity levels, and industrial uses.

Sintered ZnS: Available as sintered targets, pressed discs, or granules, these are typically produced by hot-pressing ZnS powder. With purities around 99.99%, sintered ZnS is primarily used in anti-counterfeiting coatings, dielectric films, and high-end decorative coatings.

ZnS Crystals: Produced by physical vapor deposition (PVD), ZnS crystals can reach purities above 99.99%. Thanks to their superior precision compared to sintered ZnS, they are used not only for decorative purposes but also for optical and infrared coatings—such as cold light filters, optical filters, high-reflective coatings, and IR films.

ZnS Powders: Typically appearing as a fine white-to-pale yellow powder with micron-sized particles, ZnS powders find broad use in phosphorescent materials, coatings, pigments, plastic modification, and even as a filler in brake pads.

From Lab Bench to Luminescent Material: How Zinc Sulfide is Made

The preparation of zinc sulfide is a classic inorganic synthesis. While industrial production processes are more complex, the fundamental chemistry is surprisingly simple: it only requires the reaction of a soluble zinc salt with a soluble sulfide source.

In the laboratory, one of the most common methods involves reacting zinc sulfate (ZnSO₄) with sodium sulfide (Na₂S):

The Reaction: The two compounds are dissolved in water and mixed together.

ZnSO₄(aq) + Na₂S(aq) → ZnS(s) + Na₂SO₄(aq)Precipitation: A white ZnS precipitate forms immediately, since ZnS is practically insoluble in water.

Filtration and Washing: The precipitate is filtered out, thoroughly washed with distilled water to remove sodium sulfate impurities, and then dried.

Doping (for phosphors): To prepare glow-in-the-dark variants, trace amounts of a copper salt (e.g., CuSO₄) are added to the solution before precipitation. The Cu²⁺ ions incorporate into the growing ZnS crystals, creating the trapping centers necessary for persistent phosphorescence.

On an industrial scale, ZnS is often produced by bubbling hydrogen sulfide gas (H₂S) through zinc salt solutions. The resulting precipitate is then annealed (heated at high temperature) to optimize its crystal structure and luminescent properties.

Safety Note: These processes involve hazardous chemicals, and some methods release highly toxic H₂S gas. Such syntheses should only be carried out by trained professionals in fully equipped laboratories with proper safety controls.

Beyond the Glow: Key Applications

Optical Components and Window Materials: Thanks to its wide bandgap and high refractive index, transparent ZnS is used to manufacture infrared windows and lenses. Its excellent transmission in both visible and infrared regions makes it invaluable in military thermal imaging scopes, forward-looking infrared (FLIR) systems, and laser optics.

Electroluminescence: When an alternating current is applied directly across a thin plate of copper-doped ZnS, the material emits light. This principle is harnessed in electroluminescent (EL) panels, backlighting for watches and instrument displays, and even in certain flexible night lamps.

Pigments: With its high opacity, brightness, and stability, white ZnS serves as a practical, non-toxic pigment in plastics, coatings, and paints—often used as a safer alternative to lead-based pigments.

Catalysis: Due to its high surface area, ZnS can function as a catalyst in certain organic reactions, including photocatalytic water splitting and the degradation of organic pollutants—making it relevant to green chemistry.

Electronics: As a wide bandgap semiconductor, ZnS is also studied as a candidate material for blue LEDs, photodetectors, and thin-film solar cells.

From illuminating children’s bedrooms to enabling advanced military optics, zinc sulfide demonstrates how a simple inorganic compound can play profound and multifaceted roles in modern technology. It truly is a “hidden gem”—both literally and metaphorically—whose glow (in the physical sense and as a driver of innovation) continues to push technology forward.