Niobium oxide is a high-performance material known for its outstanding properties. Thanks to its unique chemical and physical characteristics, it plays an essential role in a wide range of advanced technologies. This article offers a detailed introduction to this versatile material, including its types, properties, applications, and proper storage practices.

1. What is niobium oxide?

Niobium oxide is a general term referring to several oxides of niobium that exist in four oxidation states: Niobium monoxide (NbO or Nb2O2), Niobium dioxide (NbO₂), Niobium sesquioxide (Nb₂O₃), and Niobium pentoxide (Nb₂O₅).

Niobium monoxide (NbO or Nb₂O₂)

A black cubic crystal with metallic luster and good metallic conductivity. It dissolves in sulfuric acid, hydrochloric acid, and alkalis, but is insoluble in water, nitric acid, and ethanol. It can be prepared by reducing niobium oxychloride with magnesium. Because it is easily oxidized in air, it is relatively rare.

Niobium dioxide (NbO₂)

A black powder that dissolves in hot alkaline solutions but is insoluble in water, nitric acid, and ethanol. It can be prepared by reducing niobium pentoxide with hydrogen at elevated temperatures.

Niobium sesquioxide (Nb₂O₃)

A blue-black solid with a melting point of 1780 °C. It can be produced by reducing niobium pentoxide with metallic magnesium.

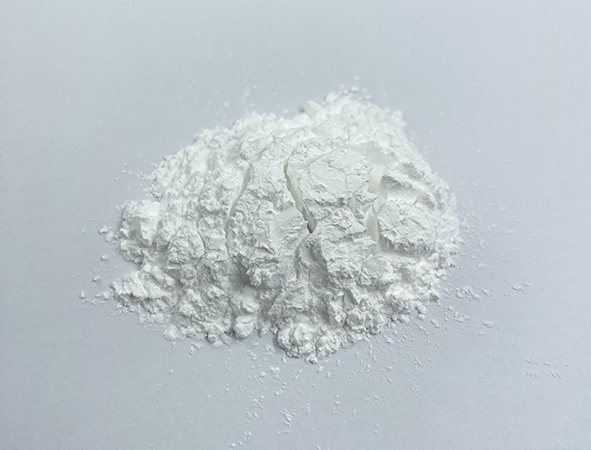

A white solid powder with a melting point of 1485 °C. It is the most stable niobium oxide. It is insoluble in water but dissolves in hydrofluoric acid, hot sulfuric acid, and alkalis. It can be prepared by roasting metallic niobium in air or by dehydration of niobic acid. Because of its outstanding stability and wide applicability, Nb₂O₅ is the most important and commonly used niobium oxide.

2. What is niobium pentoxide?

Niobium pentoxide is a white crystalline powder with the chemical formula Nb₂O₅ and a molecular weight of 265.81 g/mol. It has a high melting point and excellent thermal stability, making it a typical high-temperature ceramic material.

Physical properties: Niobium pentoxide has a relative density of 4.47 g/cm³, a hardness of 7.5–8, and a melting point of 1485 ± 5 °C. With a band gap ranging from 3.4 to 5.3 eV, it is a typical n-type transition metal oxide semiconductor.

Chemical properties: Niobium pentoxide is insoluble in water but soluble in strong acids and alkalis. It reacts with many oxides and acidic substances. For example, it reacts with sodium hydroxide to form sodium niobate. Nb₂O₅ exhibits multiple polymorphic forms, and phase transitions depend on the starting materials, pressure, and temperature.

Crystal structure: Niobium pentoxide has several crystal structures, including monoclinic, orthorhombic, and cubic forms. Depending on the synthesis temperature, it can be classified into low-, medium-, and high-temperature phases. Among them, the orthorhombic β-Nb₂O₅ phase is the most common and demonstrates excellent thermal stability, mechanical strength, and optical performance.

3. What are the uses of niobium oxide?

Niobium oxide has a broad range of applications, mainly including:

Metallurgical industry: This sector is the largest consumer of niobium pentoxide, accounting for approximately 85–90% of total niobium consumption. Applications include steel additives, high-temperature alloys, superconducting alloys, and specialty niobium metal materials.

Electronics industry: Applications in electronics have grown rapidly in recent years. Although the total volume is relatively small, the growth rate exceeds that of other industries. Nb₂O₅ is used in the production of lithium niobate single crystals, specialty optical glass, high- and low-frequency capacitors, and piezoelectric ceramic components. It is also used to produce ferroniobium and various niobium alloys for special steels, as well as catalysts and refractory materials.

Ceramic materials: Due to its excellent high-temperature resistance and chemical stability, niobium oxide is widely used in ceramic materials. It can serve as a matrix material for high-temperature structural and refractory ceramics, and as an additive to enhance mechanical properties and thermal stability.

Nanotechnology: Niobium oxide nanomaterials possess large specific surface areas and high activity. They are used in the fabrication of nanosensors, catalysts, and energy storage materials.

4. How should niobium oxide be stored?

To prevent moisture absorption or contamination during storage, suitable packaging materials should be used. Airtight plastic bags or metal containers are recommended, ensuring that the packaging does not chemically react with the oxide.

Niobium oxide should be stored in a dry, cool environment, away from high temperatures and humidity. Elevated temperatures may cause chemical changes, while moisture may lead to caking or degradation. Ideally, storage temperatures should be kept below 25 °C with relative humidity under 60%. Direct sunlight and prolonged air exposure should also be avoided to maintain product quality.

Niobium oxide is a chemical material with excellent properties and broad application prospects. During production and use, attention must be paid to its chemical characteristics and storage conditions to ensure product quality and safety.

With continuous advancements in science and technology, the application scope of niobium oxide will continue to expand. In the future, its use in new energy, advanced materials, and environmental protection fields is expected to grow significantly. Meanwhile, improvements in production technology and cost reduction will further enhance both output and quality.