Niobium alloy C103 is a high-performance niobium-based alloy widely used in aerospace and high-temperature applications. It is primarily composed of niobium (Nb) with alloying elements like hafnium (Hf) and titanium (Ti), which enhance its mechanical properties, oxidation resistance, and overall durability in extreme environments.

Composition

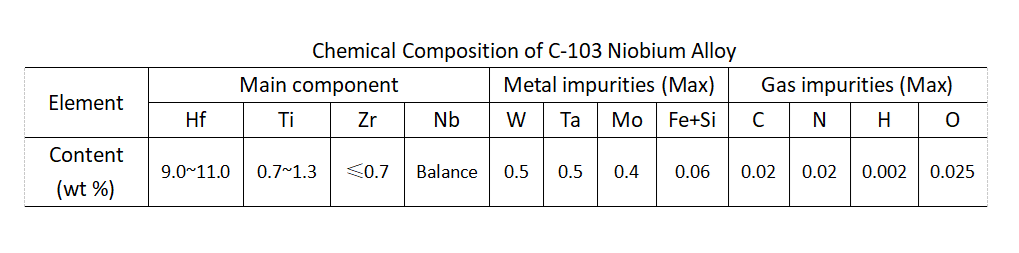

The typical composition of C-103 is:

- Niobium (Nb): ~89%

- Hafnium (Hf): ~10%

- Titanium (Ti): ~1%

This combination provides a unique balance of strength, heat resistance, and oxidation protection.

This alloy achieves solid solution strengthening by adding Hf, Ti and Zr alloy elements, among which Zr has a significant strengthening effect, and Hf and trace amounts of W mainly improve high-temperature properties.

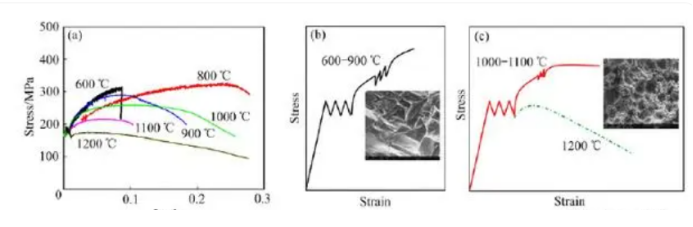

PANWAR S S, PRASAD K, UMASANKAR PATRO T and others studied the tensile properties and fracture behavior of C-103 alloy in the temperature range between room temperature (RT) and 1200 ℃ (see the figure below), between room temperature and 1200 ℃ The stress-strain curve of the alloy showed jagged fluctuations, and the dynamic strain aging (DSA) phenomenon occurred. The temperature change also has a great influence on the fracture mechanism of the alloy, that is, from room temperature to 500 ℃, 600 to 900 ℃, and 1000 to 1200 ℃. The fracture mechanisms are ductile fracture, cleavage fracture and intergranular fracture respectively.

Performance

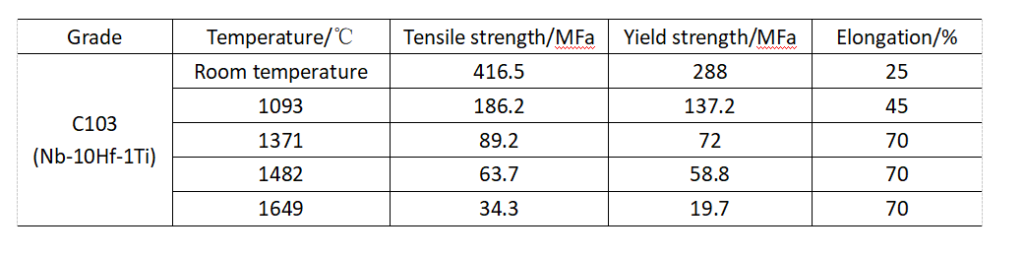

C103 niobium alloy has excellent physical and mechanical properties, mainly including high strength, high hardness, good corrosion resistance and high temperature performance. The following are the main performance indicators of C103 niobium alloy:

- Strength: C103 niobium alloy has high yield strength and tensile strength, which can reach more than 1500MPa at room temperature.

- Hardness: The hardness of C103 niobium alloy decreases with increasing temperature, but it can still maintain a high hardness at high temperature.

- Density: It is about 8.57 g/cm³, which strikes a balance between strength and weight, which is very important in aerospace applications.

- Corrosion resistance: C103 niobium alloy has good corrosion resistance in high temperature oxidizing atmosphere.

- High temperature performance: C103 niobium alloy has a high melting point and high temperature strength, and can maintain excellent performance at high temperature.

- Fatigue performance: C103 niobium alloy has good fatigue performance and can work for a long time under high cyclic stress conditions.

Heat treatment

Importance: Heat treatment is a key link in the production process of C103 niobium-hafnium alloy. Through appropriate heat treatment processes, the elements in the material can be evenly distributed to ensure that the mechanical and physical properties of the material are optimal.

Impact: The heat treatment process has a significant impact on the strength, toughness, hardness and other properties of the material. In the actual production process, the appropriate heat treatment process should be selected based on the chemical composition of the material and specific working conditions.

Application

Due to its excellent physical and mechanical properties, C103 niobium alloy is widely used in aviation, aerospace, energy and other fields. The following are the main application areas of C103 niobium alloy:

- Aerospace field: C103 niobium alloy is used to manufacture high-temperature components of jet engines and rocket engines, such as turbine blades, combustion chambers, etc.

- Energy field: C103 niobium alloy is used to manufacture structural materials for nuclear reactors and structural components of high-temperature furnaces.

- Mechanical manufacturing field: C103 niobium alloy is used to manufacture high-strength and high-corrosion-resistant mechanical parts, such as bolts, nuts, etc.

- Other fields: C103 niobium alloy can also be used in the manufacture of high-temperature components in other fields such as electronics and chemistry.

Advantages

- High temperature resistance.

- Excellent creep resistance.

- Good formability and machinability at high temperatures.

- Excellent for high stress, high heat environments.

Niobium alloy C103 is a specialized, high-performance material designed for extreme temperature and pressure conditions. The combination of niobium, hafnium and titanium has excellent mechanical properties, making it an indispensable material in aerospace and energy applications, especially where high heat and durability are critical.