Anhydrous lithium chloride, this seemingly ordinary inorganic compound, actually plays an irreplaceable role across multiple fields. As an inorganic substance, its molecular formula is LiCl, with a molecular weight of 42.39 g/mol. It exists as white crystals, exhibits deliquescence, possesses a salty-bitter taste, and is highly soluble in water, ethanol, acetone, pyridine, and other organic solvents.

The applications of anhydrous lithium chloride are astonishingly diverse, holding significant importance across industries including pharmaceuticals, refrigeration, batteries, ceramics, and catalysts. Its excellent chemical properties and physical characteristics grant lithium chloride an irreplaceable position within these sectors, providing robust support for the advancement of various industries.

I. Industrial Applications

Industrial-Scale Production

Molten Salt Electrolysis for Lithium Metal Production: Anhydrous lithium chloride serves as a vital raw material in the molten salt electrolysis process for producing metallic lithium. Metallic lithium is not only one of the most strategically significant materials for national defence but also finds extensive applications across numerous aspects of daily life, such as battery manufacturing.

Battery Production

Lithium-ion Batteries: Anhydrous lithium chloride plays a crucial role in lithium-ion battery manufacturing. It serves as a component of the electrolyte, enhancing the battery’s conductivity and stability. Additionally, anhydrous lithium chloride is utilised in preparing cathode materials, supporting their weight and significantly influencing battery performance and lifespan.

Other Industrial Applications

Welding Flux: Anhydrous LiCl serves as a flux or fluxing agent for welding metals like aluminium, improving weld quality.

Dehumidifier: Within air conditioning and climate control systems, it functions as a desiccant, absorbing moisture from the air to maintain dry indoor environments.

Catalyst: Within the chemical industry, anhydrous lithium chloride serves as a catalyst in the production of polymeric materials such as polyphenylene sulphide. Employing lithium chloride as a catalyst reduces reaction temperatures and accelerates reaction rates, thereby enhancing production efficiency and lowering energy consumption.

II. Research Fields

Semiconductor Materials: Anhydrous lithium chloride serves as a crucial raw material for semiconductor material doping agents, reducing material resistivity and enhancing electrical conductivity. Consequently, within the electronics industry, it is extensively employed in the production of semiconductor materials such as silicon germanium.

Organic Structural Analysis: In organic chemistry research, anhydrous Licl serves as a vital cationic additive for applications including organic structural analysis.

III. New Materials Sector

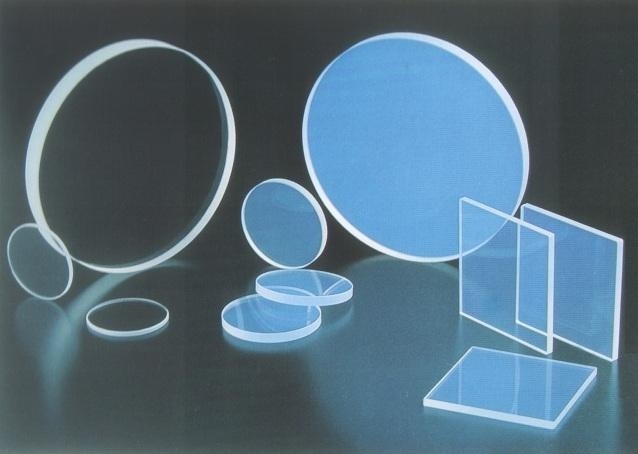

Specialty Glass Materials: Anhydrous LiCl is also employed in the production of specialty glass materials such as lithium oxide glass and lithium aluminosilicate glass. These specialty glass materials exhibit characteristics including high purity, high optical transmittance, and high thermal expansion coefficient, finding extensive application in high-tech fields.

Optical Glass: During optical glass production, the addition of LiCl modifies the glass’s refractive index and transmittance, thereby adjusting its optical properties.

Nuclear Energy Sector: Anhydrous lithium chloride is also employed in preparing lithium-lead coolants for nuclear reactor cooling and heat transfer, as well as serving as an enrichment agent and extractant for nuclear fuel.

IV. Other Applications

Ceramic Industry: Anhydrous lithium chloride also finds application within the ceramic sector. It serves as a glaze component and glaze treatment agent, enhancing the transparency and texture of glazed surfaces. Additionally, it is utilised in the production of ceramic pigments to improve the lustre of ceramic materials.

Metallurgical Industry: Anhydrous lithium chloride serves as an excellent cleaning agent for non-ferrous metals such as aluminium, zinc, lead, and magnesium, removing impurities from their surfaces. Furthermore, it functions as a flux in metal welding, casting, and alloy preparation processes.

Medical field: In recent years, anhydrous lithium chloride has gained extensive application in biology and medicine. For instance, it is employed medically to treat conditions such as mania and bipolar disorder. As a mutagenic agent, it is utilised across food, pharmaceutical, and environmental sectors for selecting superior microbial strains, cultivating high-yielding cultures, and synthesising pharmaceutical intermediates.

In summary, anhydrous lithium chloride possesses extensive application domains and significant economic value. With the advancement of new energy sectors and continuous progress in electronics, glass, ceramics, metallurgy, and related industries, its application scope will expand further. Concurrently, ongoing scientific and technological advancements will enhance lithium chloride production processes and quality, driving rapid development within the lithium chloride industry.