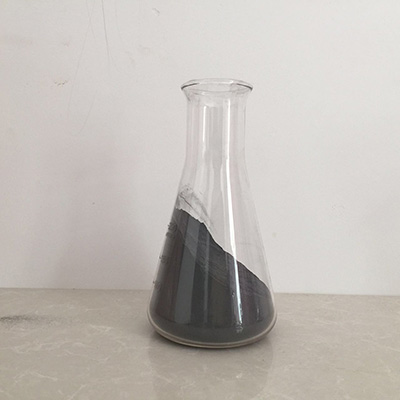

In the field of advanced manufacturing and new materials, hafnium (Hf) is renowned for its high melting point, excellent corrosion resistance, and strong neutron absorption capability. With the rapid development of powder metallurgy and additive manufacturing (3D printing) technologies, traditional irregular hafnium powders can no longer fully meet the requirements for high-precision and high-performance components. Consequently, spherical hafnium powder has emerged as a key raw material for advanced manufacturing.

Characteristics and Advantages

Compared to conventional irregular hf metal powder, spherical hafnium powder offers significant advantages in terms of morphology and performance:

Excellent flowability: The regular spherical particles allow for uniform distribution during 3D printing and laser melting processes, improving forming precision.

High packing density: Reduced interparticle voids enable the production of denser sintered components.

High purity and low impurities: Meets the strict requirements for high-purity materials in aerospace and electronics industries.

Good formability: Facilitates one-step fabrication of complex structures, reducing post-processing requirements.

These features make spherical hafnium powder an ideal choice for high-performance alloys, precision components, and high-temperature ceramic materials.

Spherical hafnium powder specifications

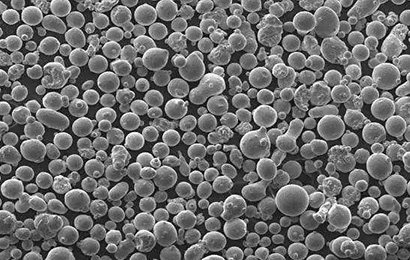

The specifications of spherical hafnium powder are generally classified based on particle size, purity grade, and other physical-chemical properties:

Particle size: Common ranges include 15–45 μm, 45–75 μm, and 75–150 μm. Smaller particles are suitable for high surface activity applications, while larger particles are better for filling and additive manufacturing.

Purity grade: Typically classified as industrial grade (≥99%) and high-purity grade (≥99.9%). High-purity spherical hafnium powder is mainly used in high-end applications sensitive to impurities, such as electronics and nuclear industries.

Flowability: Measured by a Hall flowmeter, common values are 25–35 s/50 g. Good flowability ensures uniform powder distribution during processing.

Apparent density: Generally ranges from 2.5–4.0 g/cm³. High-density powders contribute to the densification and mechanical performance of the final product.

These specifications directly affect the suitability of spherical hafnium powder for different processes and the performance of the final products.

Properties spherical hafnium powder applications

Hafnium spherical powder is widely used in multiple industrial sectors due to its excellent performance:

Aerospace industry: Often used to manufacture high-temperature alloy components such as turbine blades and engine parts. Its high melting point and corrosion resistance ensure component reliability under extreme conditions.

Nuclear industry: Hafnium’s strong neutron absorption makes spherical hafnium powder ideal for manufacturing control rods and shielding materials in nuclear reactors, enhancing safety.

Electronics industry: High-purity spherical hafnium powder can be used in capacitors and semiconductor materials, with stable electrical properties that improve electronic component efficiency.

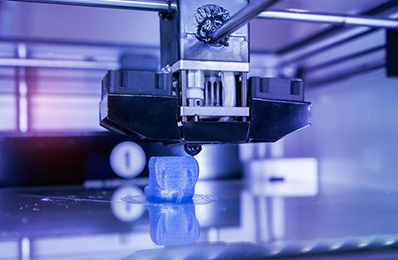

Additive manufacturing: In 3D printing, spherical hafnium powder hf metal serves as a metal powder material for fabricating complex structures, and its excellent flowability ensures smooth printing processes.

Chemical equipment: Its corrosion resistance makes spherical hafnium powder an ideal material for reactor linings and pipeline coatings, extending equipment lifespan.

Storage and Handling Considerations

Although spherical hafnium powder is relatively stable, the following precautions should be observed during storage and handling:

Moisture protection: Hafnium powder is sensitive to moisture and should be stored in a dry environment, avoiding contact with water.

Oxidation prevention: Hafnium may oxidize at high temperatures; therefore, handling under inert gas protection (e.g., nitrogen or argon) is recommended.

Safety protection: Personal protective equipment, such as gloves and masks, should be worn to prevent inhalation or skin contact.

Transportation requirements: Use sealed containers and avoid severe vibration during transport to maintain powder integrity.

Future Development Trends

With continuous advancements in aerospace and nuclear technology, there is an increasing demand for materials with high purity, fine particle size distribution, and batch-to-batch stability. The future development of spherical hafnium powder may focus on:

Finer particle sizes: Producing smaller spherical powders to meet the needs of miniaturization and high-performance applications.

Composite applications: Combining spherical hafnium powder with other materials to develop multifunctional new materials, such as reinforced ceramics or metal matrix composites.

Environmentally friendly processes: Optimizing production to reduce energy consumption and waste, improving sustainability.

Exploring new fields: With the growth of new energy and advanced manufacturing industries, spherical hafnium powder may find applications in solar cells, electric vehicles, and other emerging areas.

As a critical industrial material, the specifications and properties of spherical hafnium powder directly influence the quality of the final product. By understanding its common specifications and applications, readers can better appreciate the value of this material. With continuous technological innovation, spherical hafnium powder is expected to play an increasingly important role across various industries in the future.