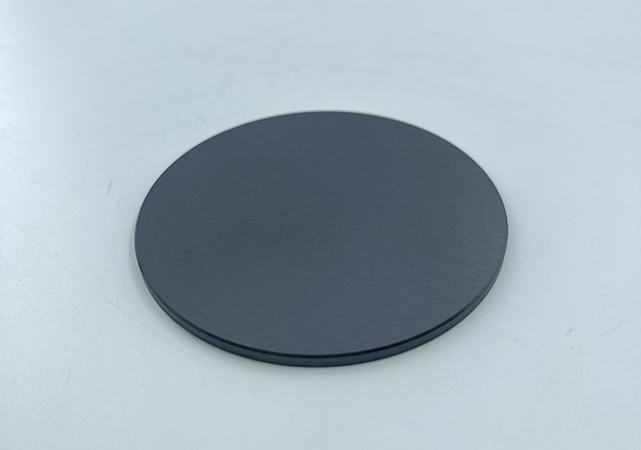

Niobium pentoxide targets are high-purity ceramic materials used in physical vapor deposition (PVD) processes. With a typical purity of 99.99%, they serve as key source materials for fabricating functional thin films in optical coatings, semiconductor devices, and other advanced applications.

As an advanced material that integrates excellent chemical stability with outstanding optical and electrical properties, Niobium pentoxide targets play a critical role across a wide range of high-tech industries. The following sections provide a comprehensive analysis of their material characteristics, fabrication technologies, and core applications.

I. What's the properties of Niobium PentoxideTargets?

Niobium pentoxide targets are high-density ceramic products formed through specialized processing techniques. Their main constituents are niobium (Nb) and oxygen (O). When the purity reaches 99.99% (commonly referred to as 4N), impurities are minimized to extremely low levels, resulting in superior and stable performance. Their key properties include:

1. Excellent Physical Characteristics: Niobium pentoxide features a high melting point, high hardness, and strong chemical stability. The dense and uniform structure of the target ensures stable and consistent plasma generation during sputtering, enabling the deposition of uniform, high-quality thin films. Its thermal expansion coefficient matches well with common substrates such as silicon and glass, reducing the risk of film cracking or delamination caused by thermal stress.

2. Unique Optical and Electrical Properties: Thin films deposited from high-purity Niobium oxide targets exhibit a high refractive index, broad optical transparency from the visible to near-infrared range, and low optical loss. They also demonstrate excellent dielectric performance, including a relatively high dielectric constant and low dielectric loss, making them highly valuable in microelectronic applications.

3. Outstanding Chemical Stability: Nb₂O₅ films are highly inert to most acids, alkalis, and organic solvents, providing exceptional corrosion resistance. They maintain stable performance under natural environmental conditions and are not easily oxidized or chemically degraded, ensuring long-term reliability in demanding environments.

4. Environmental Friendliness: As an inorganic, non-toxic material, Nb₂O₅ does not release harmful substances during production or use, meeting modern industrial requirements for environmentally friendly and sustainable materials.

Comparison with Other Materials

Compared with other oxides, niobium oxide demonstrates superior chemical stability, high-temperature resistance, and balanced optical and electrical performance. For example, compared with zinc oxide (ZnO) and titanium dioxide (TiO₂), Nb₂O₅ offers a higher refractive index and better electrochemical stability.

Competitive advantages: Its unique combination of properties makes Nb₂O₅ particularly suitable for applications requiring high thermal stability, chemical durability, and advanced optoelectronic performance.

II.How to make Niobium Pentoxide Targets?

Powder Metallurgy

This method involves pressing Niobium pentoxide powder followed by high-temperature sintering to form solid targets. It offers simple processing, relatively low cost, and suitability for large-scale production. However, the resulting density and uniformity may be slightly lower than those achieved by other techniques, which can affect performance.

Physical Vapor Deposition (PVD)

PVD converts Nb₂O₅ from solid to vapor phase and then deposits it onto substrates to form thin films. This method allows precise control over film thickness and composition, producing high-purity and highly uniform films. It is ideal for demanding applications in optoelectronics and semiconductors. Its limitations include higher equipment and operating costs and relatively lower production efficiency.

Chemical Vapor Deposition (CVD)

CVD deposits Niobium oxide films through chemical reactions of niobium-containing gaseous precursors at elevated temperatures. It enables atomic-level control of film growth and can produce high-quality films with complex structures, even at relatively low temperatures. It is well suited for advanced optoelectronic devices but involves complex processes, high costs, and strict precursor requirements.

Application Scenarios

Powder metallurgy: Suitable for large-area, cost-sensitive industrial coating applications.

PVD: Ideal for high-purity, high-uniformity, and precisely controlled films used in high-end optoelectronics and precision devices.

CVD: Best for complex structures and specialized films required in advanced semiconductor and nanotechnology research.

III. What's the use of Niobium PentoxideTargets?

The applications of Niobium pentoxide targets arise from the synergy of their multiple properties rather than any single characteristic.

Optical and Optoelectronic Fields: Their high refractive index and low absorption make them ideal for precision optical coatings used in camera lenses, lasers, and optical sensors, improving light transmission or enabling wavelength-selective functions. Such films are also widely used in smartphone camera modules and other consumer electronics.![]()

Microelectronics and Semiconductors: Their high dielectric constant is crucial in this field. Nb₂O₅ films serve as gate dielectrics or capacitor dielectric layers in high-performance memory devices and integrated circuits, supporting continued device miniaturization while meeting stringent capacitance requirements.

Functional Glass and Energy-Saving Coatings: By combining chemical stability with optical performance, Nb₂O₅ is used in coatings for architectural and automotive glass to produce low-emissivity (Low-E) layers that transmit visible light while reflecting infrared radiation, improving thermal insulation and energy efficiency.

New Energy and Aerospace: Thanks to their excellent dielectric properties, chemical stability, and resistance to high temperatures and radiation, Niobium oxide targets are used to fabricate functional and protective layers in batteries and photovoltaic devices, enhancing efficiency and durability. In aerospace applications, they are also applied as protective and thermal-control coatings for optical and electronic components, ensuring reliable long-term performance in harsh environments.

Scientific Research and Specialized Functional Materials: As source materials for functional oxide films, niobium pentoxide targets are used in electrochromic devices, gas sensors, catalytic supports, and other advanced systems, enabling cutting-edge research in optical, electronic, and catalytic technologies.

IV. Precautions for Using Niobium Pentoxide Targets

Storage conditions: Store in a dry environment free of corrosive gases to prevent moisture absorption or oxidation.

Sputtering parameters: Optimize power, pressure, and temperature during sputtering to avoid overheating, cracking, or film degradation.

Safety protection: Nb₂O₅ powder may be irritating; wear protective masks and gloves to prevent inhalation or skin contact.

High-purity (99.99%) niobium pentoxide targets are far more than ordinary industrial materials; they are critical enabling materials endowed with multiple advanced physicochemical properties. Like a versatile “canvas,” they transfer their superior characteristics onto product surfaces through advanced thin-film deposition technologies, quietly yet decisively enhancing optical performance, ensuring electronic reliability, promoting energy efficiency, and supporting next-generation information technologies. With continuous advances in material processing and growing application demands, high-purity niobium pentoxide targets and their thin-film products will demonstrate even greater value across an expanding range of technological frontiers.