Indium tin oxide (ITO) targets, as a key class of transparent conductive oxide materials, play a central role in many modern high-tech industries. Combining high optical transparency with excellent electrical conductivity, they are the essential starting materials for producing transparent conductive thin films. This article presents a systematic overview of high-performance ITO targets, covering their fundamental definition and properties, manufacturing routes, and cutting-edge application fields, in order to illustrate the technological journey from powder to functional products.

What Is Indium Tin Oxide Target?

Basic Definition

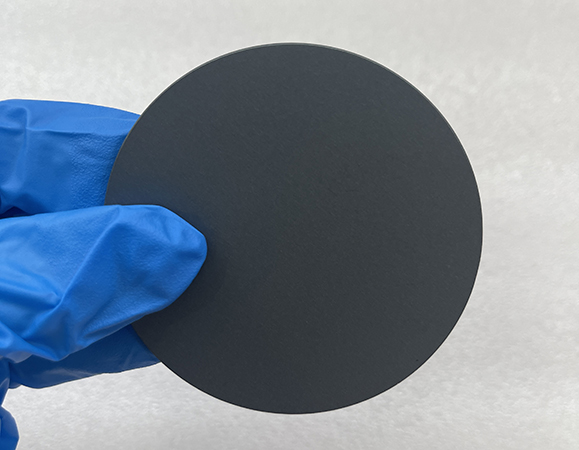

An indium tin oxide ito target is not an ordinary ceramic block, but a functional composite material made by combining indium oxide (In₂O₃) and tin oxide (SnO₂) in a carefully controlled ratio, typically about 90% indium oxide and 10% tin oxide by weight. This ratio is not a simple mixture; rather, it is precisely optimized to achieve the best balance between electrical conductivity and optical transparency.

Indium oxide itself is an n-type semiconductor that provides a high concentration of free charge carriers, giving it good electrical conductivity. The addition of tin oxide introduces a doping effect that further increases the carrier concentration, enhancing conductivity while maintaining high optical transparency. At the same time, this combination helps suppress resistivity fluctuations caused by oxygen vacancies, resulting in more stable electrical performance. Owing to this carefully engineered material system, ITO targets can be converted into thin films by physical vapor deposition and related techniques, enabling the films to exhibit both “transparency” and “conductivity”—two properties that would otherwise appear contradictory.

From a materials science perspective, the performance of transparent conductive films is governed by the electronic structure, crystal structure, and defect density of the material. Indium oxide has a wide bandgap of about 3.6 eV, which gives it high transparency in the visible range, while tin oxide contributes to enhanced electrical conductivity. Their combination therefore provides ITO with outstanding transparent conductive properties, making it a widely used material in displays, photovoltaics, and many other fields.

Physical Properties of ITO Targets

ITO targets are characterized by high optical transparency, excellent electrical conductivity, and good mechanical and thermal stability, which together make them ideal for optoelectronic devices.

In terms of transparent conductivity, ITO films typically maintain a transmittance of 80–90% in the visible spectrum, allowing most visible light to pass through without compromising optical performance. At the same time, they exhibit high surface conductivity, with typical resistivity values on the order of 10⁻⁴ Ω·cm. This unique combination ensures that ITO can simultaneously function as a transparent optical medium and an efficient electrical conductor.

Mechanical stability is equally important, especially because ITO is often used in devices that require long-term reliability, such as displays and solar cells. The dense crystal structure of ITO enables it to withstand mechanical stress and environmental loading, while its relatively low thermal expansion coefficient gives it good dimensional stability. Even under high temperature or high-vacuum conditions, ITO films maintain stable physical properties.

ITO also exhibits excellent thermal stability. This allows it to retain its optical and electrical performance under elevated temperatures, which is critical for devices exposed to sunlight, high operating temperatures, or high-temperature sputtering processes. Its ability to tolerate thermal fluctuations ensures stable performance in demanding manufacturing and operating environments.

How Is Indium Tin Oxide Targets Produced?

The fabrication of ITO targets is a sophisticated process that integrates materials science, precision engineering, and chemical processing. It requires not only high-purity raw materials but also carefully controlled manufacturing and finishing steps to ensure excellent physical and chemical performance.

Powder Preparation and Pretreatment

The process begins with high-quality indium oxide and tin oxide powders. Their purity, particle size, and size distribution are fundamental to the final product. To achieve high performance, 4N (99.99%) or 5N (99.999%) purity powders are typically used to minimize the impact of impurities on electrical and optical properties.

Using advanced chemical synthesis and mixing techniques, ultra-fine, high-purity, and uniformly blended precursor powders are produced. Precise weighing and high-efficiency mixing methods, such as wet or dry ball milling, ensure that the two oxides are homogeneously mixed at the microscopic level. This is followed by drying and calcination, which remove volatile components and initiate solid-state reactions, forming the desired ITO solid-solution phase.

Forming Techniques

The pretreated powders are then compacted into green bodies with sufficient strength and a defined shape. Cold isostatic pressing is commonly used, in which isotropic pressure is applied through a liquid medium, resulting in highly uniform density and minimal internal defects—ideal for large, high-performance targets. Die pressing is another option for simpler shapes, though care must be taken to avoid density gradients. Small amounts of organic binders may be added to improve the mechanical strength of the green bodies for handling.

Sintering

Sintering is the most critical step in determining the final properties of ITO targets. During sintering, particles bond through high-temperature diffusion, pores are reduced, and a dense, robust microstructure is formed.

Atmospheric sintering is carried out in air or oxygen and is relatively simple, though achieving very high density can be challenging. Hot pressing combines heating with uniaxial pressure, enabling high density to be achieved at lower temperatures or in shorter times, albeit with higher equipment cost. Controlled-atmosphere sintering, such as in oxygen, allows precise regulation of oxygen vacancies, thereby tuning the electrical properties.

Cold isostatic pressing may also be used prior to sintering to produce highly uniform green bodies, while hot isostatic pressing (HIP), performed at high temperature and high isotropic pressure, can further eliminate residual porosity and achieve extremely high density and uniformity for high-end ITO targets.

Post-Processing

After sintering, the targets are machined by cutting, grinding, and polishing to achieve the required dimensions and surface flatness. For specific deposition processes such as rotating sputtering, the target may also be bonded to a backing plate to ensure good thermal and electrical contact. Throughout machining, microcracks and edge defects must be carefully controlled to avoid problems during thin-film deposition.

What Is Indium Tin Oxide Target Used For?

ITO is indispensable in a wide range of advanced technologies.

In display technology, ITO films serve as pixel electrodes in LCDs, controlling liquid crystal orientation to modulate light transmission. In OLEDs, ITO acts as the anode in contact with organic layers, directly influencing luminance, efficiency, and power consumption. For Micro-LED displays, ITO provides highly uniform, fine-line transparent electrodes that meet the demands of ultra-high resolution.

In photovoltaics, ITO functions as the front electrode in thin-film solar cells such as CIGS, CdTe, and perovskites. Its high transparency and low resistivity improve light absorption and reduce electrical losses, enabling higher power conversion efficiencies. Flexible ITO films produced by roll-to-roll sputtering also support the development of bendable solar cells.

In touch panels and sensors, ITO films are used as transparent electrodes in capacitive touchscreens, offering high sensitivity and precision. Their biocompatibility and conductivity also make them suitable for biosensors, such as glucose sensors that detect concentration changes through current variation.

In smart buildings and automobiles, ITO is used in electrochromic windows to dynamically control light transmission, reducing energy consumption, and in transparent heating films for defogging and de-icing windshields and mirrors.

Challenges and Outlook

Despite its technological maturity, ITO faces challenges, particularly due to the scarcity and cost of indium. This has driven research into reducing indium content and developing alternative transparent conductive materials. Nevertheless, the fabrication of high-performance ITO targets remains a highly refined process involving materials science, powder metallurgy, and precision machining. Continuous optimization of every processing step is unlocking ever better material performance. As demand for high-performance transparent conductors continues to grow, deeper understanding and innovation in ITO target fabrication will ensure that this material remains indispensable across future high-tech industries.