What is zirconium powder?

Zirconium powder is a gray metallic powder (chemical symbol Zr) with a high melting point, excellent corrosion resistance, and flammability. It is widely used in the nuclear industry, aerospace, and electronic devices. Spherical zirconium powder is an optimized form of zirconium powder, in which the particles have a regular spherical shape. This morphology provides advantages such as good flowability and high packing density, making it more suitable for applications in powder metallurgy, 3D printing, and ceramic additive manufacturing.

Physical properties: melting point 1852 °C, boiling point 4377 °C, density 6.49 g/cm³. Insoluble in water, but soluble in hot concentrated acids, hydrofluoric acid, and aqua regia.

Chemical reactivity: its surface readily forms an oxide film; at high temperatures it reacts directly with oxygen, nitrogen, and hydrogen. When exposed to air, it may spontaneously ignite, burning with a white flame to form zirconium oxide.

Can zirconium powder explode?

Zirconium powder is a fine metallic particle with highly flammable and explosive properties. When exposed to air or oxygen, it can undergo a violent reaction, releasing large amounts of heat and flame. Zirconium powder is also strongly irritating and corrosive, posing serious hazards to human health and the environment. Notably, zirconium powder can also burn in carbon dioxide or nitrogen atmospheres. When the powder is subjected to heat, exposed to open flames, or mixed with oxidizing agents, it may cause combustion or even explosive accidents.

If it needs to be transported from one location to another, strict safety measures must be taken, including the selection of suitable transport methods and real-time monitoring to detect abnormalities promptly. Common storage and transportation methods include:

- Water-sealed zirconium powder:Zirconium powder is often used in detonators and is classified as a flammable and explosive material. For storage and transportation, it is generally sealed under water.

- Special vacuum-sealed packaging:Since water-sealed zirconium powder requires drying before use, we can provide vacuum-sealed packaging to simplify customer handling.

Drying methods

Because zirconium powder is explosive, it must be isolated from air during the drying process.

Drying under argon or nitrogen protection;

Vacuum drying using a vacuum oven, i.e., evacuating with a mechanical pump. The temperature should preferably be around 60 °C, and the powder should only be removed once it has cooled down, usually below 30 °C.

Is Zirconium Powder Prone to Oxidation?

Zirconium powder is relatively stable at room temperature, but it is highly prone to oxidation and even spontaneous combustion under high temperatures or specific conditions. Its oxidizing tendency arises from zirconium’s strong affinity for oxygen, and the powder form significantly increases its reactivity.

Stability at room temperature: Dense zirconium or bulk zirconium can remain stable in air for long periods, as the surface oxide film prevents further reaction. However, zirconium powder, due to its high specific surface area, is more easily oxidized. When exposed to air, it undergoes slow oxidation and may accumulate heat.

High-temperature oxidizability: When heated above 100 °C, Zr powder rapidly absorbs oxygen to form zirconium dioxide (ZrO₂), and at 1000 °C, it undergoes significant volumetric expansion. Its ignition point is around 400 °C, at which it burns with intense light, producing zirconium dioxide.

What is zirconium powder used for?

Zirconium powder is an important metallic material with wide-ranging applications in the nuclear industry, chemical industry, aerospace, electronic components, medical devices, and corrosion protection. Its excellent properties and versatile applications make it one of the indispensable materials in modern industry.

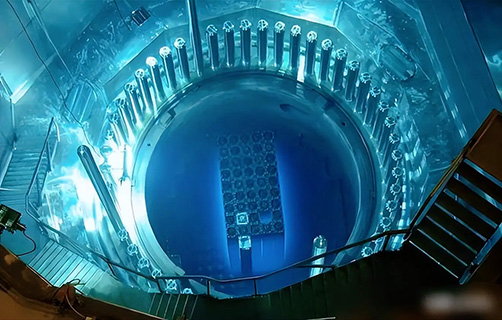

- In the nuclear industry, due to its outstanding corrosion resistance and high-temperature performance, zirconium powder is widely used in the manufacturing of fuel rods for nuclear reactors. Fuel rods are the fundamental components of a nuclear reactor, and their quality and performance are crucial for the safe operation of the reactor. Using zirconium powder ensures that the fuel rods have high strength and corrosion resistance, thereby extending their service life and ensuring the safe operation of the reactor.

- In the chemical industry, it can be used to produce high-performance chemical catalysts. These catalysts are widely applied in petroleum refining, organic synthesis, and environmental protection. The high surface area and active surface of zirconium powder enhance the reaction rate and selectivity of catalysts, improving production efficiency and product quality.

- In the aerospace field, it can be used to produce ultra-high-temperature alloys. These alloys can withstand extreme temperatures and pressures, ensuring the safety and reliability of spacecraft.

- In electronic components, it can be used to manufacture high-performance capacitors and resistors, improving the stability and reliability of electronic circuits.

- In the medical device field, it be used to produce high-quality artificial joints and dental implants, enhancing patients’ quality of life and health.

- In corrosion protection, zirconium metal powder can be used to produce high-performance anti-corrosion coatings, which protect buildings and equipment from corrosion and oxidation.

Is zirconium stronger than titanium?

Titanium generally has higher strength than zirconium, especially after alloying (such as Ti-6Al-4V), with a tensile strength of 900–1200 MPa, whereas pure zirconium is around 330–680 MPa. Titanium has a lower density (about 4.5 g/cm³), giving it a superior strength-to-weight ratio, and it is commonly used in aerospace, medical implants, and high-performance structural materials.

Zirconium’s mechanical strength is lower than that of titanium, but it exhibits excellent corrosion resistance, particularly in acidic environments and nuclear reactor conditions. Due to its higher density (about 6.5 g/cm³), zirconium has a disadvantage in strength-to-weight ratio, but it offers unique advantages in chemical corrosion resistance and high-temperature performance.