Evaporation coating materials are essential for vacuum evaporation processes and thin-film deposition in modern manufacturing. From semiconductor devices and optical coatings to OLED displays and aerospace components, high-purity evaporation materials directly determine coating quality and device performance.

In this article, we’ll walk through the fundamentals of evaporation coating, common material types, key consumables, and real-world applications—helping you understand how material selection directly impacts coating performance.

I. What Is Evaporation Coating?

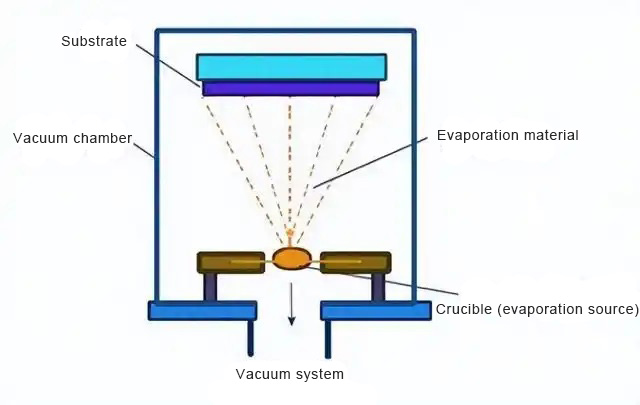

Evaporation coating, also known as vacuum evaporation, is a physical vapor deposition (PVD) process. Under high vacuum, a material is heated until it vaporizes and then condenses onto a substrate, forming a thin and uniform film.

Because the process relies primarily on thermal energy, it is often referred to as thermal evaporation. In some cases, electron-beam heating is used for materials with very high melting points.

Evaporation coating is widely applied as a surface treatment technique, improving appearance, performance, and durability in industries such as semiconductors, optics, and advanced electronics.

How Does Evaporation Coating Work?

The evaporation process consists of three key stages:

Material evaporation: Evaporation coating materials are heated using resistance heating or electron beam sources.

Vapor transport: In a high-vacuum environment, evaporated atoms travel freely with minimal collisions.

Film condensation: Vaporized atoms condense on the substrate surface, forming a uniform thin film.

High vacuum conditions are essential, as they allow precise control over film thickness and composition—critical for microelectronics, optical coatings, and energy devices.

II. Common Evaporation Coating Materials

Depending on composition and application requirements, evaporation materials generally fall into four categories.

1). Metal Materials

Common metals include aluminum, chromium, copper, nickel, silver, titanium, and zinc. Metal evaporation coatings provide metallic luster, enhanced surface hardness, and improved corrosion resistance, and are widely used for decoration, protection, and electrical conductivity.

2). Alloys

Alloy materials such as nickel-chromium, copper-nickel, and brass allow fine-tuning of film properties. They are often used where enhanced corrosion resistance or stable electrical performance is required.

3). Compound Materials

Oxides: Aluminum oxide (Al₂O₃), zinc oxide (ZnO), etc. Oxide coatings offer diverse colors and surface properties and are commonly used in decorative finishes, ceramic coatings, and optical films.

Nitrides: Silicon nitride(Si₃N₄), aluminum nitride(AlN), etc. Nitride coatings enhance hardness, wear resistance, and high-temperature stability, and are widely used in cutting tools, automotive components, and aerospace materials.

Carbides: Tungsten carbide(WC), titanium carbide(TiC), etc. Carbide coatings significantly improve hardness and wear resistance, making them suitable for tools, bearings, and protective coatings.

Fluorides: Magnesium fluoride (MgF₂), dysprosium fluoride (DyF₃), etc. Fluoride coatings exhibit excellent optical properties such as high transmittance and high laser damage thresholds, and are commonly used in anti-reflection coatings, high-power laser optics, and precision optical systems.

Sulfides: Zinc sulfide (ZnS), cadmium sulfide (CdS), etc. Sulfide materials possess favorable optical and electrical properties, including high refractive indices and tunable bandgaps, and are widely applied in infrared optics, photodetectors, display devices, and semiconductor applications.

4). Organic Evaporation Materials

Organic evaporation materials are critical for OLED display manufacturing and organic photovoltaic devices. These materials enable high-efficiency light emission and excellent color performance in modern displays.

III. Key Consumables in Evaporation Coating

In addition to coating materials themselves, various consumables are required during the vacuum evaporation process. Although these consumables do not directly form the thin film, they play a critical role in ensuring process stability and film quality.

1) Evaporation Sources

Evaporation sources are the core components of vacuum coating systems and are used to heat materials for evaporation. Resistance heating sources are suitable for low-melting-point materials, while electron-beam sources provide high energy density and are ideal for high-melting-point materials. Induction heating and arc heating sources are also used for specific applications.

2) Shield Plates

During evaporation, some materials may vaporize prematurely and contaminate equipment. Shield plates, typically made of high-temperature-resistant materials, are used to block stray vapor and protect system components, thereby improving film quality.

Quartz crystal monitors measure and control film thickness in real time by detecting changes in oscillation frequency. They offer high precision, fast response, and excellent stability.

4) Vacuum Pumps

Vacuum pumps are used to establish and maintain the high-vacuum environment required for evaporation. Mechanical pumps are typically combined with diffusion pumps or molecular pumps, and their performance directly affects coating quality.

IV. How to Prepare Evaporation Materials?

The preparation of evaporation materials generally includes mixing, raw material pretreatment, forming, sintering, and inspection.

Raw materials are first mechanically mixed to ensure uniform distribution, followed by room-temperature or high-temperature pretreatment to enhance purity, refine particle size, activate reactivity, and reduce sintering temperatures.

The materials are then shaped to the required specifications through mechanical forming. After forming, high-temperature sintering promotes particle bonding and produces dense polycrystalline structures with specific microstructures.

Finally, the finished materials are tested using evaporation coating equipment to verify whether performance indicators meet required standards.

V. What's Evaporation Coating Materials Used For?

Semiconductor Manufacturing: Evaporation materials are widely used to deposit conductive, insulating, and semiconducting films, such as aluminum and copper layers in chip fabrication.

Optical Coatings: Used to produce anti-reflection coatings, high-reflection coatings, and optical filters by precisely controlling film thickness.

Displa Panels: Evaporation materials are key raw materials for OLED displays, forming emissive layers and charge transport layers.

Aerospace Industry: Used to create protective coatings for aerospace structures, including corrosion-resistant, wear-resistant, reflective, and thermal barrier films.

Surface Protection and Coatings: Applied to tools and mechanical components to enhance hardness and reduce friction. In medical devices, evaporation coatings provide antibacterial and biocompatible surfaces.

VI. How to Choose the Right Evaporation Coating Material?

Key considerations when selecting evaporation materials include:

Purity Requirements: High purity is essential to ensure excellent electrical and mechanical properties and to prevent defect formation.

Composition Control: Accurate control of element ratios in multicomponent films requires precise evaporation source management and monitoring.

Thermal Stability: Materials must remain stable at evaporation temperatures (e.g., aluminum oxide must remain stable below 2000 °C).

Chemical Inertness: Evaporation source and crucible materials must be compatible to avoid unwanted reactions (e.g., tungsten crucibles for high-melting-point metals).

VII. Special Materials and Process Challenges

Some materials present unique challenges:

1). Multicomponent Compounds: Materials such as perovskites (CsPbBr₃) require co-evaporation or flash evaporation, with composition control accuracy within ±2%.

2). Highly Volatile Materials: Selenium (Se) evaporates easily at low temperatures (~200 °C), requiring precise temperature control.

3). Environmental Regulations: Cadmium-based materials are being gradually replaced by zinc oxide due to toxicity concerns.

VIII.Conclusion

Vacuum evaporation coating is a key thin-film deposition technology for high-performance electronic, optical, and display applications. As demand for advanced devices continues to grow, high-purity evaporation coating materials will remain essential to achieving consistent quality and long-term reliability.

Investing in the right materials—and a reliable evaporation material supplier—ensures better coating performance and production efficiency.