DEPOSITION MATERIALS

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) is a one-stop source of thin film deposition materials. Our products cover a series of sputtering targets (including planar targets, rotating targets, ring targets, etc.), evaporation materials (including granules, pellets, pieces, shots, beads, tablets, etc), backing plates, bonding services, etc.

Our products cover pure metal materials, alloy materials, oxide materials, halide materials, various ceramic deposition materials such as carbides/nitrides/borides/silicides, and rare earth materials.

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) is dedicated to offering services tailored to design novel target materials that align with your specific process requirements. If you have any questions about sputtering targets and evaporation materials, don’t hesitate to contact us.

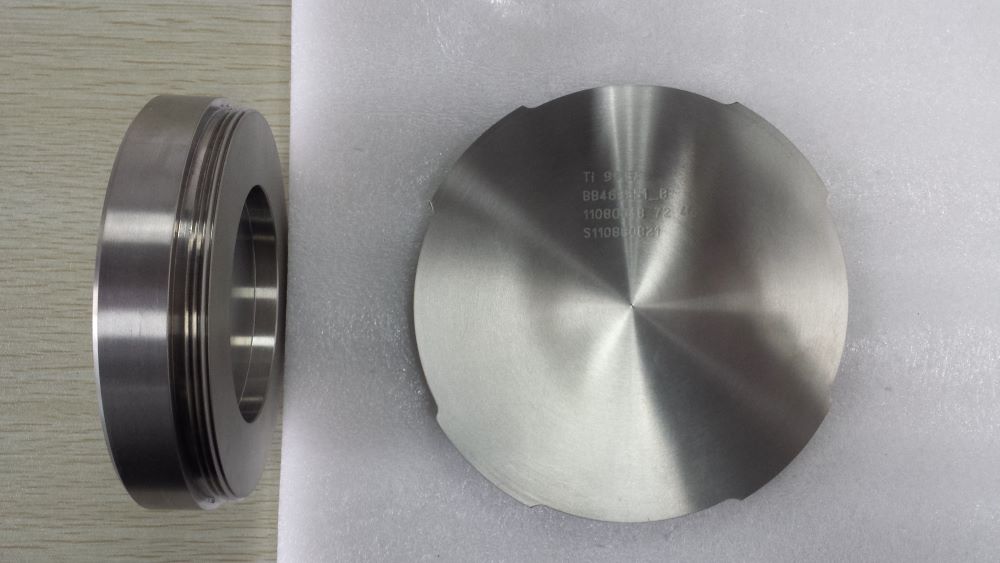

Planar Sputtering Targets

We provide the most comprehensive range of high-purity and high-performance planar sputtering targets, available in all materials and typically in the shape of discs or rectangular plates.

Planar targets are essential materials used in physical vapor deposition (PVD) processes, especially sputtering. These targets are usually flat and rectangular or circular, hence the term “planar.” During the sputtering process, ions bombard the surface of the planar target, causing atoms or molecules to be ejected from the target material. These ejected particles then deposit onto a substrate, forming thin films with specific properties.

Our sputtering targets feature high purity, excellent uniformity, and fine grain size, which have a significant impact on coating quality, widely used in industries such as electronics, semiconductors, solar energy, and optics. They are critical in the production of microchips, display screens, photovoltaic cells, and coatings for various devices. These targets can be made from metals, alloys, ceramics, or other compounds, depending on the desired film characteristics.

Evaporation Materials

We offer a wide range of ultra-high purity chemical vapor deposition materials, utilizing melting and sintering techniques, including metals and oxides.

Evaporation deposition materials are substances used in thin-film deposition processes, particularly in thermal evaporation or electron-beam evaporation (commonly known as “e-beam”). These processes involve heating the material to a point where it transitions from a solid or liquid phase to vapor, which then condenses onto a substrate, forming a thin film. They are essential in industries such as semiconductors, optics, solar cells, and protective coatings.

Our evaporation deposition materials deliver optimal evaporation performance, representing the most advanced coating results to meet the stringent requirements of your scientific research, process development, or full-scale production. All shapes are available, including pellets, granules, shots, beads, tablets…

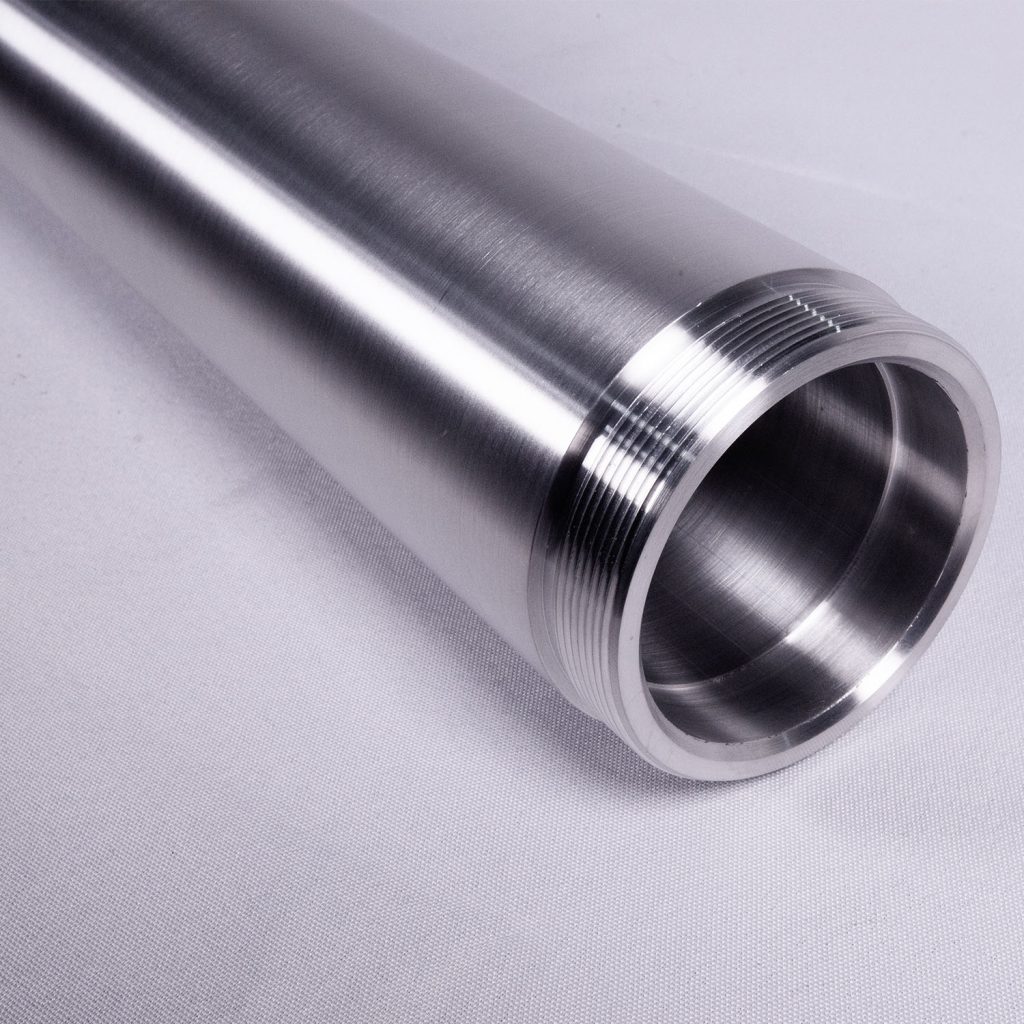

Rotary Sputtering Targets

Our rotary sputtering targets feature a mature production process. They have a compact structure and higher utilization, addressing the low utilization issue of planar targets while maintaining high uniformity during large-area coating.

The working principle of the rotary target is to increase the uniformity of the film by rotating the target material itself. This design ensures that the material deposited on the target surface is more uniform, improving the quality and efficiency of the coating.

If you have specific size requirements, please send us your drawings, and we will customize the targets according to your specifications.

SPUTTERING TARGETS, EVAPORATION MATERIALS

PVD is one of the main technologies for preparing thin film deposition materials. PVD coating deposition materials primarily include sputtering targets and evaporation materials. With the development of thin film technology and its applications, VI HALBLEITERMATERIAL GmbH (VIMATERIAL) is committed to providing innovative solutions and creating sustainable value for our customers.

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) strives to be a trusted partner for our clients and play a significant role in the thin film industry.