Sputtering target is a physical vapor deposition technology. It is a process in which ions generated by an ion source are accelerated and gathered in a vacuum to form a high-speed ion beam, bombarding the solid surface. The ions exchange kinetic energy with the atoms on the solid surface, causing the atoms on the solid surface to leave the solid and deposit on the substrate surface.

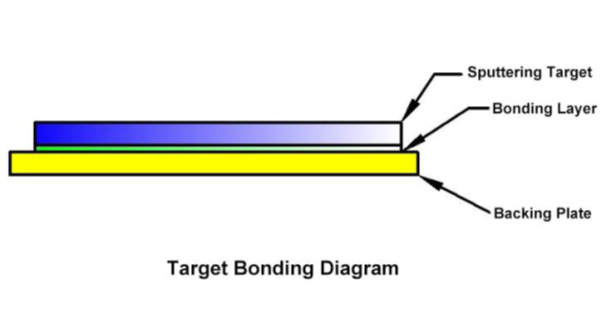

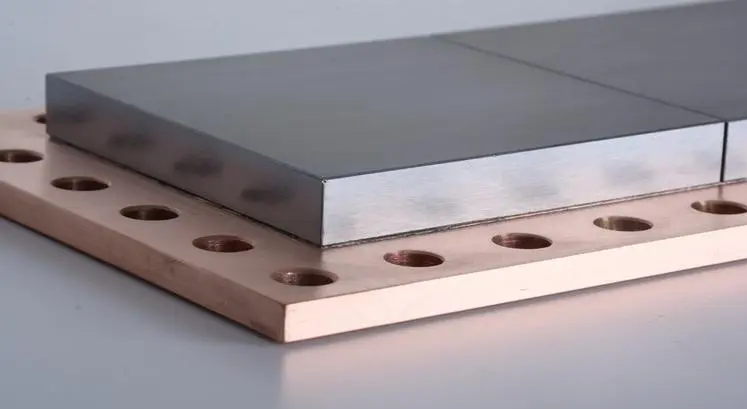

In order to prevent brittle metals, alloys, oxides and other easy-to-break materials from breaking during use, we can provide customers with target bonding services. The target is bound to a copper backing plate. In addition to protecting the target from accidental breakage during transportation or handling, it can also ensure good cooling and electrical contact of the target, and can improve the problem of insufficient mechanical strength when the target is used or solve the problem of limited large-size target.

The backing plates used for target bonding are generally copper, titanium, molybdenum and stainless steel. The backing plate supports the target during sputtering to prevent the target from cracking during sputtering and improve the utilization rate and service life of the target.

VI HALBLEITERMATERIAL GmbH (VIMATERIAL) offers sputtering target bonding services with three primary modes: adhesive bonding, solder bonding, and high-temperature welding. Our typical approach utilizes solder technology, employing metal indium as the solder and copper for the backplate.

Bonding range: metal target, ceramic target, alloy target, rotating target, flat target, round target, special-shaped target.

Bonding materials may vary depending on the target material. We invite inquiries for specialized requirements.

Main target bonding modes of targets

1. Adhesive combination

Silver adhesive bonding is a low-cost technology. The method is to bond the target to the backplane with a special thermally conductive and electrically conductive epoxy resin.

This technology requires treatment of the surface of the target and the backplane. The bonded target has low residual stress and is easy to rework. Its tangent point thermal resistance is relatively large, which will limit the power density and deposition rate of the sputtering target. This method does not work well.

2. Solder bonding

Compared with silver adhesive bonding, solder bonding has lower thermal resistance and can therefore operate at higher deposition rates. A common solder filler is indium, which has high thermal conductivity, relatively low melting point and elastic modulus, which can reduce residual stress after bonding. Its low melting point also simplifies the rework of the bonding and allows the backplane to be reused. The bonding process can be carried out in the air, reducing the bonding cost.

However, since indium metal is not easy to penetrate the copper backplane and the target, it is easy to drop the target, which requires ultrasonic penetration of metal indium into the backplane and the target. This is a common high-efficiency and low-cost method in recent years.

3. High temperature welding

High temperature welding is a technique that combines brazing and diffusion welding. It needs to be operated above 500°C and requires a vacuum or controlled atmosphere oven. Brazing is achieved by melting the brazing alloy at the joint to form a joint. Instead of using fillers, welding achieves bonding by heating the backing plate at high pressure to a temperature that interdiffusion with the target material.

This structure has a low thermal resistance, usually close to or lower than the thermal resistance of the parent alloy, and allows for higher power density. But this method is costly.

BONDING LAYER PERFORMANCE REQUIREMENTS

Thermal Conductivity:

In magnetron sputtering, high-energy ions bombard the target surface, generating significant heat. Inefficient heat dissipation can lead to rapid temperature increase in the target material, causing issues such as target desoldering, melting, and equipment overheating, potentially leading to equipment malfunction or damage.

Effective thermal management is achieved by connecting the target to the backplate via a bonding layer and employing circulating cooling water.

Conductivity:

In magnetron sputtering, the target, acting as a cathode, requires good electrical conductivity with the target holder to maintain optimal sputtering rates and target lifespan.

Strength:

The target bonding layer must possess sufficient strength to support the target’s weight, ensuring it remains securely in place during use.

TARGET BONDING PROCESS

- Surface pre-treatment of the target and backplate (Clean up the debris and dust on it);

- Placement of the target and backplate on the welding table, followed by heating to the required welding temperature (Generally 180 degrees);

- Metallization of the target and backplate (Ultrasonic indium);

- Application of adhesive to the target and backplate;

- Adjustment of the target bonding position (Pressure block on the target);

- Cooling and subsequent post-processing steps.

Why do we need to bonding?

1. Prevent the target from being unevenly heated and broken, such as brittle targets such as ITO, SiO2, ceramics and sintered targets;

2. Save costs and prevent deformation. If the target is too expensive, the target can be made thinner and bound to the back target to prevent deformation.

Precautions for bonding targets

- The sputtering temperature should not be too high;

- The current should be increased slowly;

- The circulating cooling water should be below 35 degrees Celsius;

- Appropriate target density.

The requirements for high-quality target bonding are very demanding.

Bonding must select low thermal resistance materials so that the highest possible power can be applied when the target is used without causing overheating and cracking of the target;

The porosity after bonding must also be minimized to avoid the possibility of target cracking and uneven deposition;

The bonding must be strong enough to prevent the target from being unbound during operation, but must be flexible enough to minimize the formation of residual stress during the bonding process. The latter stress may cause the target to break.

Finally, the target bonding can easily separate the target and the back plate so that the back plate can be reused.

If you want to know more about sputtering targets, target bonding and other technologies, please consult VIMATERIAL!