Niobium C-103 Alloy: Pushing the Limits of Performance and Leading a New Era of Ultra-High-Temperature Materials

As a high-performance refractory metal alloy, C-103 alloy stands out for its exceptional resistance to high temperatures, corrosion, and mechanical stress. It plays a critical role in aerospace, energy equipment, chemical processing, and other high-end manufacturing fields. The following sections provide a detailed overview of C-103’s key characteristics, applications, and future development trends.

I. What's C-103 Alloy

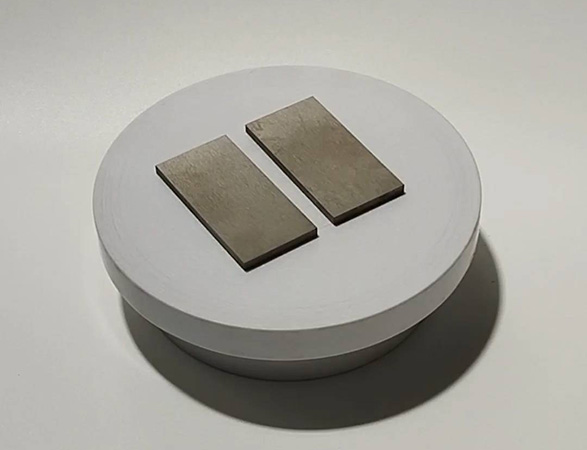

C-103 alloy is a high-temperature alloy based on niobium (Nb), typically containing about 10% hafnium (Hf) and 1% titanium (Ti), along with trace elements such as zirconium (Zr), vanadium (V), carbon (C), and oxygen (O). This composition provides several major advantages:

It remains stable above 1,200 °C and has a melting point as high as 2,468 °C — far exceeding that of common stainless steels (e.g., 304 stainless steel melts at 1,400–1,450 °C).

At 1,200 °C, it maintains a tensile strength of 85 MPa (about 40% higher than conventional niobium alloys), making it ideal for rocket nozzles, jet engine components, and other extreme-temperature parts.

Its dense oxide layer provides strong protection against acidic and oxidizing environments, performing particularly well in strong corrosive media such as sulfuric and nitric acid. With HfC-SiC gradient coatings, oxidation rates can be kept ≤ 0.5 mg/cm²·h at 1,400 °C.

Compared with traditional refractory metals, C-103 alloy is more easily fabricated, reducing manufacturing costs. Ultra-thin components (down to 0.2 mm) can be processed at 950–1050 °C.

With a room-temperature tensile strength of 380–450 MPa and a yield strength ≥ 1,500 MPa (after high-temperature strengthening), C-103 alloy maintains structural stability under prolonged high-temperature and high-stress conditions—critical for applications requiring extreme reliability.

II. What's the C-103 Alloy used for?

♻️ Aerospace

C-103 alloy is a preferred material for rocket engine nozzles, combustion chamber liners, and turbine blades. These components face intense temperature and pressure conditions, and C-103’s high-temperature strength and creep resistance significantly improve efficiency and reduce fuel consumption.

♻️ Nuclear Energy

In nuclear reactors, C-103 alloy’s resistance to neutron radiation and hot coolant corrosion makes it suitable for fuel cladding, heat-exchanger tubes, and other high-temperature radiation-resistant components.

♻️ Defense Industry

C-103 alloy is widely used in thermal-protection systems for hypersonic vehicles and in guidance systems for missiles, where extreme temperatures and high-speed aerodynamic forces demand exceptional material stability and precision.

♻️ Chemical Equipment

Used in high-temperature furnaces, semiconductor equipment, and corrosion-resistant reactors.

III. Why Choose Niobium-Hafnium Alloy C-103?

Proven Reliability: Decades of engineering validation, with widespread adoption in top-tier programs from NASA, SpaceX, and others.

Customizable Supply: Composition can be tailored to optimize mechanical performance and manufacturability.

Globaly Recognized: Complies with ASTM, AMS, and other international standards for assured quality.

In the pursuit of higher speed, greater efficiency, and more advanced technology, the C-103 niobium-hafnium alloy continues to push the boundaries of high-temperature material science. Whether for space exploration or energy innovation, C-103 is a trusted partner.

IV. Future Development Trends

With advancing technology and growing industrial demand, C-103 alloy is expected to evolve in the following ways:

With its high-temperature strength, lightweight potential, and fabrication versatility, C-103 will continue to dominate the market for aerospace thermal-structure components and is expected to find new applications in sixth-generation jet engines, fusion reactors, and other advanced technologies.

C-103 alloy’s unique properties make it an irreplaceable “super-material” in modern industry. As space exploration and clean-energy development accelerate, its market potential will only continue to grow. Looking forward, C-103 is poised to deliver even greater value across a wider range of fields and contribute to technological progress worldwide.