What is silicon nitride?

Silicon nitride, with the chemical formula Si3N4, is a new type of inorganic non-metallic material composed of silicon and nitrogen in a specific ratio. It is an important member of the family of advanced structural ceramics.

It possesses the following key characteristics:

- High strength and hardness

- Excellent wear resistance and thermal shock resistance

- Outstanding high-temperature performance (1200–1400 °C)

Unlike alumina (Al2O3), silicon nitride exhibits superior mechanical strength and thermal shock resistance at elevated temperatures, allowing it to combine both structural and functional properties — it can bear mechanical loads while also serving as an electrically insulating and thermally conductive material in electronics and semiconductor applications.

Crystal Structure and Characteristics

Silicon nitride exists in two crystalline forms: α-Si3N4 and β-Si3N4, both belonging to the hexagonal crystal system.

α-Si3N4: forms granular crystals, typically generated at lower temperatures, with higher chemical reactivity that facilitates densification during sintering.

β-Si3N4: forms needle-like crystals, stable at higher temperatures. The strong Si-N covalent bonds in this phase endow silicon nitride with exceptional mechanical strength.

Mechanical and Physical Properties

Silicon nitride has a Mohs hardness of about 9, giving it outstanding wear resistance and the ability to withstand friction and abrasion, thereby extending service life. Its low density (approximately 3.2 g/cm³) offers significant advantages in lightweight design.

At high temperatures, silicon nitride’s surface rapidly forms a dense silicon dioxide (SiO₂) protective layer, which acts as a robust shield against further oxidation. This self-protective film ensures material stability even under high-temperature and corrosive environments.

In addition, Si3N4 demonstrates excellent electrical insulation, making it a promising material for use in electronic and semiconductor applications.

What are the properties of silicon nitride?

| Property | Typical Performance | Significance |

|---|---|---|

| Low Density | ~3.2 g/cm³ | Lighter than metals, ideal for weight-reduction structures |

| High Strength | Flexural strength about 800–1000 MPa | High load-bearing capacity, resistant to fracture |

| Thermal Conductivity | 20–90 W/m·K | Essential for heat dissipation in high-power devices |

| Thermal Stability & Shock Resistance | Maintains performance at elevated temperatures | Ensures stable operation in high-temperature environments |

| Electrical Insulation | High dielectric strength | Suitable for electronic component substrates |

| Corrosion & Oxidation Resistance | Stable in acid, alkali, and high-temperature oxidative atmospheres | Extends service life |

These properties make silicon nitride ceramics the material of choice in aerospace, new energy, semiconductors and high-end machinery.

Does HF etch silicon nitride?

As a high-hardness material, silicon nitride (Si3N4) requires specific chemical solutions for effective etching. In semiconductor fabrication, one chemical that engineers both “love and fear” is hydrofluoric acid (HF). Hydrofluoric acid can etch silicon nitride, producing silicon tetrafluoride (SiF4) and ammonium fluoride (NH4F) according to the following reaction:

Reaction Equation:

Si3N4 + 12 HF → 3 SiF4 + 4 NH4F

In this reaction, fluoride ions (F⁻) from HF combine with silicon atoms in Si₃N₄ to form soluble SiF₄, while nitrogen atoms react with hydrogen ions (H⁺) to form NH₄F.

The etching of Si3N4 by HF is a chemical corrosion process, and its rate depends on factors such as solution temperature, HF concentration, and mass transport efficiency. For instance, in semiconductor manufacturing, a buffered HF solution (BHF)—which typically contains ammonium fluoride—is commonly used to control the etching rate and maintain stable pH conditions.

What is silicon nitride used for?

Silicon nitride, as a new type of inorganic non-metallic material, is widely used in semiconductors, optoelectronics, aerospace, and other fields. Its specific applications include:

Materials Science:

Si3N4 is an excellent structural material, widely used in the production of ceramic tools, coating materials, bulletproof materials, and high-strength fibers.

Semiconductor Industry:

Positioned between silicon carbide (SiC) and silicon dioxide (SiO₂) in properties, silicon nitride is highly compatible with Si and SiO₂ films. It is often used as a dielectric layer or isolation layer in semiconductor devices. For example, silicon nitride films are used in the fabrication of non-volatile memory and transistors.

Aerospace Industry:

With excellent high-temperature stability and low thermal conductivity, silicon nitride is widely used in heat-resistant components, ceramic bearings, and gap-seal parts for aircraft, spacecraft, and rocket engines.

Optoelectronics Industry:

Silicon nitride serves as an excellent electrical insulator, optical material, and lens material. It plays an important role in manufacturing lasers, optical fiber communication devices, LEDs, and LCD backlight sources.

Silicon Nitride (Si3N4) Processing and Customization

With modern precision processing technologies, silicon nitride can be produced in a variety of forms and tailored to high-precision specifications. The main forms we offer include:

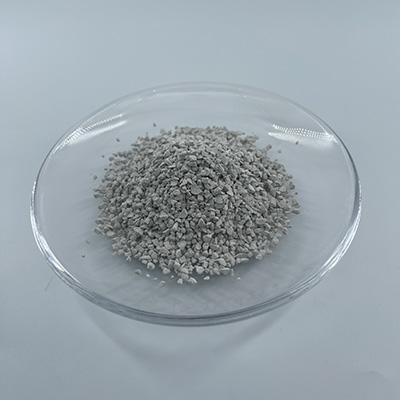

Powder — Core raw material for manufacturing high-performance silicon nitride ceramic products.

Granules — Used as a key additive or primary component to enhance the performance of traditional refractory materials.

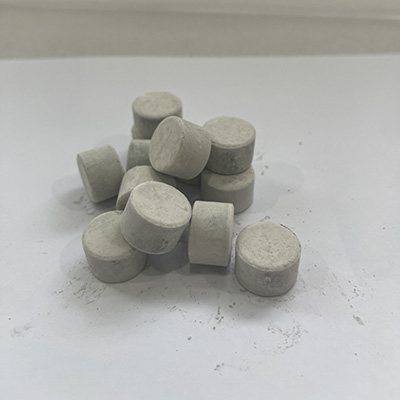

Pellets — Used as sintering green bodies or directly consumed in specific industrial applications.

Targets — Typically applied in specialized thin-film or sputtering processes.

Ceramic Components — Can be manufactured as flat plates, dielectric sheets, substrates, wear-resistant plates, etc.

Composite Material Customization

Silicon nitride can be combined with silicon carbide, boron nitride, metallic phases (Mo, W), or oxides to tailor properties such as thermal conductivity, electrical conductivity, and thermal expansion. This enables reliable performance in high-temperature and high-wear environments.

Rapid Prototyping and Small-Batch Customization

We support small-batch trials during research or new product development stages.

Customizable Options (Customer-Selectable)

Chemical Purity (e.g., 99%, 99.5%, etc.)

Particle Size Distribution / D10-D50-D90 / Average Particle Size (nm–μm scale available)

Particle Shape (spherical, near-spherical, flake, irregular)

Surface Treatment (coating, hydrophilic/hydrophobic treatment, flow modification)

Type and Amount of Additives (affects sintering temperature and final intergranular phases)

Forming Method (dry pressing, isostatic pressing, injection molding, slip casting, etc.)

Densification Process (Hot Pressing / HIP / Pressureless Sintering)

Final Dimensions and Tolerances (e.g., ±0.1 mm, depending on size and processing method)

Mechanical, Thermal, and Electrical Properties (flexural strength, hardness, fracture toughness, thermal conductivity, thermal expansion coefficient)

Testing Reports / Certifications (particle size, elemental analysis by ICP/OES, XRD, density, microstructure, RoHS/REACH if required)

Packaging and Release Inspection (vacuum bags, inert gas, desiccant, moisture-proof boxes)

Future Development Trends of Silicon Nitride

With the continuous advancement of materials science, the preparation and processing technologies of silicon nitride are expected to become more diverse and efficient. Future research is likely to focus on the following areas:

Improving Density and Purity:

By optimizing sintering processes and adding suitable auxiliary materials, internal defects can be minimized and overall material performance enhanced. This will broaden the application of silicon nitride in high-end technology fields.

Reducing Costs:

Developing more economical production techniques, especially those that lower the energy consumption of high-temperature processes, will enable large-scale, cost-effective production to meet industrial demands.

Enhancing Processability:

Although silicon nitride exhibits excellent properties, it is currently difficult to machine and shape. Future research will focus on improving its processability through the introduction of appropriate secondary phases or new processing technologies, making it easier to form and manufacture.

Functional Development:

Beyond maintaining its intrinsic superior properties, silicon nitride may be endowed with new functionalities, such as improved thermal conductivity or enhanced radiation resistance, to meet the specific requirements of diverse applications.