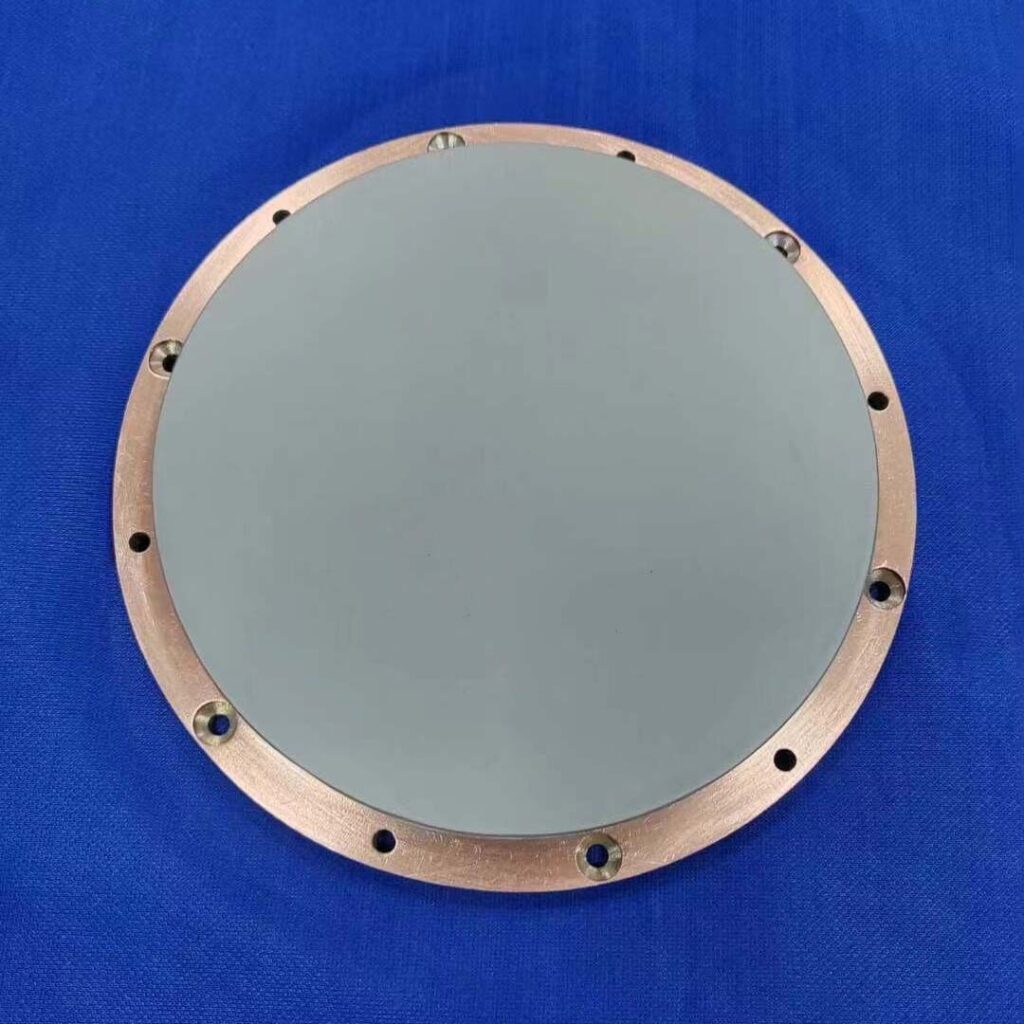

Sputtering targets are materials used to prepare thin films. They are mainly used in the sputtering process of physical vapor deposition (PVD) technology. As the source of materials, sputtering targets themselves are generally metals or compounds with extremely high purity. Sputtering targets are not only widely used in the electronics industry, but also in optoelectronics, energy, chemistry, medicine and life sciences.

I. Classification of sputtering targets

According to different preparation processes and application fields, sputtering targets can be divided into many types, including metal targets, alloy targets, rare metal targets, oxide targets, nitride targets, carbide targets, boride targets, sulfide targets, fluoride targets, etc.

Metal targets

Metal targets are targets made of a single metal or metal alloy, such as copper, aluminum, titanium, etc. These targets are favored for their good electrical and thermal conductivity.

Application fields: Widely used in semiconductors, memory devices, display technology and other fields. For example, copper targets are used to form fine conductive channels in integrated circuits; aluminum targets are very important in the manufacture of integrated circuits and display electrodes.

Alloy targets

Alloy targets are made of two or more metals mixed in a specific proportion and have special physical or chemical properties that a single metal target does not have.

Application fields: For example, nickel-chromium alloy targets are very useful in the manufacture of corrosion-resistant and high-temperature stable films.

Rare metal targets

Made of rare metals such as molybdenum, platinum, etc., these materials are very important in specific applications due to their unique chemical and physical properties.

Application areas: Commonly used in the manufacture of high-performance thin films, such as applications in aerospace and high-end electronics.

Oxide targets

Oxide targets are composed of metal oxides, such as indium tin oxide (ITO) and zinc oxide. These targets have excellent transparency and conductivity.

Application areas: Mainly used in the manufacture of transparent conductive films such as touch screens, liquid crystal displays, solar cells and various sensors.

Nitride targets

Nitride targets are compounds of nitrogen and metals, which generally have high thermal stability and excellent chemical stability. In addition to salts and metal nitrides, there are also covalent nitrides such as aluminum nitride, boron nitride and silicon nitride.

Application areas: Our nitride ceramic sputtering targets are used for innovative applications in rapidly developing industries, such as the solar and automotive industries, LED lighting technology, mechanical engineering and industrial technology.

Carbide targets

Carbide targets are a class of materials with extreme physical and chemical properties and excellent thermal stability at high temperatures.

Application areas: Carbide targets are widely used in semiconductors, optoelectronics, magnetic recording, solar cells and other fields.

Boride targets

Boride targets have excellent properties such as high hardness, high chemical stability and wear resistance.

Application areas: Boride targets have broad application prospects in the preparation of metal, semiconductor and ceramic thin films and the coating of solar nuclear electronic components.

Sulfide targets

Compounds composed of sulfur and metal elements have many special properties, such as high temperature stability and excellent photoelectric properties.

Application areas: Sulfide targets are widely used in the fields of chemistry, materials and electronics, and are mainly used to manufacture optoelectronic devices, such as photovoltaic cells and photoelectric sensors. They can also be used as precursors for surface covering materials, anti-corrosion materials, semiconductors and other materials, and are widely used.

Fluoride targets

Fluoride targets are suitable for the manufacture of unconventional film layers, such as zinc fluoride and calcium fluoride. These film layers have the characteristics of reflection, corrosion resistance and optical discoloration.

Application areas: They can be used in fields such as solar panels and protective mirrors.

II.Application of sputtering targets in industry

Semiconductor industry applications

In the semiconductor industry, sputtering targets are used to manufacture metal layers, insulating layers, and conductive layers in integrated circuits. The quality of these thin film layers directly affects the performance and reliability of the final product.

Commonly used targets: ultra-high purity aluminum targets, titanium targets, copper targets, tantalum targets, etc., which are mainly used to form conductive channels, while oxide targets are used to manufacture insulating layers.

The highest technical requirements in terms of performance, ultra-high purity metals, high uniformity, high precision dimensions, and high integration to meet the needs of smaller size and higher performance.

Optical film applications

Optical films are widely used in products such as displays, lenses, and windows to provide reflection, anti-reflection, and light filtering functions.

For example, silicon nitride targets are used to manufacture transparent conductive films, while aluminum or silver targets are used to manufacture reflective films.

High technical requirements in terms of performance, high purity materials, large material area, and good uniformity.

Solar cell applications

The thin film layers in solar cells can be prepared by sputtering technology, including absorption layers, transparent conductive layers, and reflective layers. The selection and preparation conditions of sputtering targets have an important impact on the photoelectric conversion efficiency of solar cells.

Commonly used targets: high-purity aluminum targets, copper targets, molybdenum targets, chromium targets, ITO targets, etc.

Performance-wise, the technical requirements are high and the application range is wide.

Magnetic film applications

Sputtering targets can also be used to prepare magnetic films for applications such as magnetic storage devices and sensors.

Commonly used targets: iron-based targets, nickel-based targets, chromium-based targets, cobalt-based alloy targets, etc., which are mainly used in optical drives, optical disks, etc.

Performance-wise, high storage density and high transmission speed.

Conductive film applications

Mainly used in applications such as electronic devices and touch screens. By controlling the sputtering conditions, films with different conductive properties can be obtained.

Commonly used targets: nickel-chromium alloy targets, chromium-silicon alloy targets, etc., which are mainly used in thin film resistors and thin film capacitors.

Performance requirements: small size, good stability, and small resistance temperature coefficient of electronic devices.

Decorative film industry

Decorative films are mainly used for appearance decoration and functional improvement of automobiles, buildings and consumer electronic products.

Key materials: Metal and alloy targets, such as chromium, nickel, titanium, etc., are widely used because they provide unique colors and gloss.

III.How to choose sputtering target?

Effect of material properties on sputtering effect

Physical properties: The melting point, thermal conductivity and electrical conductivity of the target directly affect the stability and efficiency of the sputtering process. For example, materials with high melting points and high thermal conductivities are more stable during high-temperature sputtering processes.

Chemical properties: The chemical stability and corrosion resistance of the target affect the purity and uniformity of the film. Chemically stable materials reduce impurity levels in films.

Material Purity and Sputtering Quality

Purity requirements: High-purity target materials can significantly improve the quality of the film. Lower purity targets may introduce undesirable impurities that affect the electrical and physical properties of the film.

Purity technology: To achieve high purity standards, sophisticated purification technologies such as electrolytic refining and vacuum melting are required during the production process.

Economic benefit analysis of target materials

Cost vs. Benefits: When selecting a target, there is a trade-off between material cost and expected performance. High-performance materials may cost more, but provide better sputtering results and longer service life.

Market supply: Availability of materials and market price fluctuations are also important considerations. Choosing materials that are easily available and relatively stable in price can reduce production costs and risks.

IV.Conclusion

Sputtering targets are a material used to prepare thin films and have a wide range of applications. Their quality and purity are very important for preparing high-precision thin films, so you need to be careful when purchasing sputtering targets.

VIMATERIAL has extensive experience in the target industry and can recommend the most suitable materials for you according to your needs. If you have any questions about targets, please do not hesitate to contact us.